- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Water tube steam generator

- GEA Polacel Cooling Towers bv

- Products

- Catalogs

- News & Trends

- Exhibitions

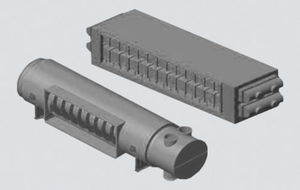

Water tube steam generator two-passheat-recovery

Add to favorites

Compare this product

Characteristics

- Firebox

- water tube

- Other characteristics

- two-pass, heat-recovery

Description

Heat Recovery Steam Generators (HRSG), for gas turbines in single and-or combined cycles and cogeneration plants.

The DELTA waste heat boiler, with a standarized modular design that fits most high-temperature flue gas heat recovery applications without custom design extra costs. The unique DELTA design offers eight different gas inlet-outlet arrangements and 60 sizes which to date are in operation downstream gas turbines with power output ranging from 1 to 25 MW.

The DELTA features a natural circulation design through the water-tube selection, promoted by unheated downcomers. To greatly extend the heating sufaces of the water tubes, serrated fins are continuously welded to the tube walls. Together with the special two-pass gas flow baffle system and the extended heating surfaces. DELTA is able to use longer and fewer tubes, and higher static head to assure better circulation.

Main characteristics of DELTA heat recovery steam generator:

The DELTA watertube heat recovery boiler is widely recognised as an industry standard for small to medium gas turbine exhaust applications. It has also found extensive use in process furnace, refinery heater and fume incinerator applications.

Catalogs

No catalogs are available for this product.

See all of GEA Polacel Cooling Towers bv‘s catalogsOther GEA Polacel Cooling Towers bv products

Shell & Tube Heat Exchangers

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Air chiller

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Compact chiller

- Tubular heat exchanger

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Blast chiller for the food industry

- Steam generator

- Oil chiller

- Compact heat exchanger unit

- Brazed plate heat exchanger

- Shell and tube heat exchanger

- Condenser

- Gas/gas heat exchanger

- Air/water heat exchanger unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.