- Hydraulics - Pneumatics

- Filter and Separator

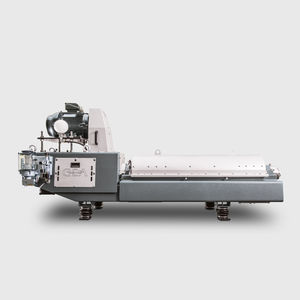

- Sludge dewatering decanter

- GEA Westfalia Separator

Sludge dewatering decanter cutMastercentrifugalhorizontal

Add to favorites

Compare this product

Characteristics

- Applications

- for sludge dewatering

- Type

- centrifugal

- Orientation

- horizontal

Description

This deep-pond decanter centrifuge has been customized for clear classification in chemical and mineral processing applications. The solid-wall bowl has a cylindrical section for efficient clarification of the liquid and a conical section for drying the solids. Due to the centrifugal forces, the solids are flung onto the inner bowl shell and are transported by the scroll to the solids discharge. On decanter type cutMaster series, the clarified liquid is discharged freely into a liquid catcher and flows off under gravity. CIP-compatability of the decanter can be assured. The housing consists of a frame with supporting feet, protective plates and catchers for the discharged phases.

GEA summationdrive

Drive with intelligent kinematics for high differential speeds and torques which enables processing of high solid capacities

Full torque up to the maximum differential speed; this allows processing of high solid capacities

High efficiency of the drive as the variable speed motor feeds in energy instead of braking

Automatic adaptation of the differential speed by means of frequency-controlled motor

Good accessibility to all drive parts

Changing the differential speed without replacing the complete gear

All product-contacting parts are made of stainless steel

Features & Benefits

All product-contacting parts are made of high-alloyed duplex steels, super duplex steels or Hastelloy C276. Depending on the application, the gaskets are made of NBR, FKM, FFKM, EPDM

Chemical cleaning after separation possible

Explosion-protected centrifuges available: ·

Catalogs

No catalogs are available for this product.

See all of GEA Westfalia Separator‘s catalogsRelated Searches

- Solid classifier

- Centrifugal classifier

- Liquids separator

- Filtration system

- Process classifier

- Liquid filtration system

- Gravity classifier

- Classifier for the food industry

- Oil separator

- Decanter centrifuge

- Horizontal decanter

- Separator for the chemical industry

- Water separator

- Self-cleaning separator

- Compact classifier

- High-efficiency classifier

- Vertical classifier

- Vacuum filtration system

- Industrial decanter

- Bulk material separator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.