- Hydraulics - Pneumatics

- Filter and Separator

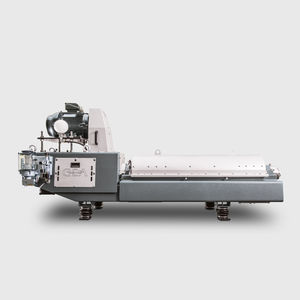

- Decanter for the beverage industry

- GEA Westfalia Separator

Decanter for the beverage industry gMaster CFcentrifugalhorizontal3-phase

Add to favorites

Compare this product

Characteristics

- Applications

- for the beverage industry

- Type

- centrifugal

- Orientation

- horizontal

- Other characteristics

- 3-phase

Description

Think plant-based: A decanter centrifuge is the indispensable tool for beverage producers to extract liquid product from mashed and watered cereal grains, ensuring high yield, optimum hygienic purity and premium taste. The slurry is fed into the GEA CF Decanter Centrifuge for the central step: to separate the undesired fibers and keep the desired starch and β-glucans in the product. This decanter has been designed for the food and beverage industry. The machine is completely CIP-able in special hygienic design.

The clarified liquid is discharged under pressure by a centripetal pump. The solids are discharged by gravity via a funnel. The product connections are designed according to DIN 118564. The machine is driven by a frequency-controlled 3-phase AC motor via V-belts. GEA summationdrive with intelligent kinematics for high differential speeds and torques which enables processing of high solid capacities. Full torque up to the maximum differential speed; this allows processing high solid capacities. High efficiency of the drive since the variable speed motor feeds in energy and does not brake. Automatic adaptation of the differential speed by means of frequency-controlled motor. All product-contacting parts are made of stainless steel. FDA-approved materials are available for the seals.

Catalogs

No catalogs are available for this product.

See all of GEA Westfalia Separator‘s catalogsRelated Searches

- Solid classifier

- Centrifugal classifier

- Liquids separator

- Filtration system

- Process classifier

- Liquid filtration system

- Gravity classifier

- Classifier for the food industry

- Oil separator

- Decanter centrifuge

- Horizontal decanter

- Separator for the chemical industry

- Water separator

- Self-cleaning separator

- Compact classifier

- High-efficiency classifier

- Vertical classifier

- Vacuum filtration system

- Industrial decanter

- Bulk material separator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.