- Packing - Handling - Logistics

- Storage

- Shuttle storage system

- GEBHARDT Intralogistics Group

Shuttle storage system Omnipallet®

Add to favorites

Compare this product

Description

Pallet shuttle storage system for maximum efficiency

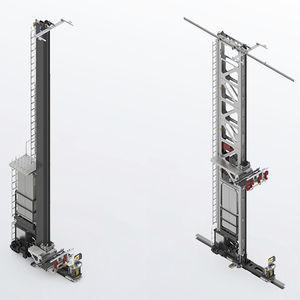

With the robot and shuttle-based GEBHARDT Omnipallet®, GEBHARDT delivers a pioneering innovation in the field of pallet storage technology. This innovation applies the already-established shuttle technology for containers and cartons to pallet conveying systems.

In contrast to the pallet SRM, the new shuttle is not permanently assigned to a rack aisle and, unlike conventional pallet shuttles, is not dependent on a parent vehicle, as both points restrict flexibility too much. For this reason, the robot moves bi-directionally. The system thus enables a variety of storage concepts, whether in cooperation with or without pallet conveyor technology. Storage can be single-deep to multiple-deep and combined in any way.

Benefits

• High scalability

• Maximum utilisation of storage capacities

• High and low capacities possible regardless of warehouse size

• Co-operation with conventional conveyor technology

• High energy efficiency - designed for continuous operation thanks to automatic loading

• Single and multi-deep storage can be freely combined

• Suitable for Industry 4.0

• Higher throughputs and greater flexibility for the storage of pallets, mesh boxes, and large load carriers

Flexible pallet shuttle for dynamic storage technology

Omnipallet® storage system automation doesn’t depend on a central core, unlike high-bay warehouses that use storage and retrieval machines. Instead, the system uses numerous small robots that move independently within the warehouse structure.

VIDEO

Catalogs

Other GEBHARDT Intralogistics Group products

Warehouse Technology and Systems

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.