- Packing - Handling - Logistics

- Storage

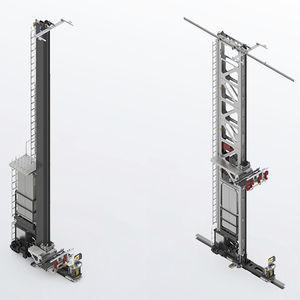

- Automatic stacker crane

- GEBHARDT Intralogistics Group

Automatic stacker crane for warehousefor storage systemsfor pallet

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Options

- for warehouse, for storage systems, for pallet, for heavy loads, for logistic centers

Description

The storage and retrieval machine (SRM) that can negotiate corners from GEBHARDT can be optimally used when pallets of up to 2,000 kg are to be stored or retrieved over several aisles in a high-bay warehouse. In accordance with its task, the storage and retrieval machine is then equipped with load handling devices (LHD).

An Overview of the Advantages

• Automate several aisles with an SRM

• Low initial investment

• Cost-effective multi-shift operation

• Easy to expand

• Small curve radius

The use of a storage and retrieval machine (SRM) that can negotiate corners is ideal where automation makes sense but throughput allows one SRM to serve multiple aisles. SRMs that can negotiate corners are in competition with conventional warehouses that operate forklift trucks. The advantage of SRMs is that they incur lower costs for personnel, operation and maintenance. In addition, multi-shift operation is a cost-effective proposition.

Compared to a warehouse serviced by forklift trucks, process reliability can be improved, throughput can be increased and operator errors can be minimised. The SRM that can negotiate corners is able to service several aisles of shelving by leaving one of the aisles then driving into a different aisle via a system of rails and points. This system offers the advantages of an automatic warehouse at lower investment costs than an SRM solution with 'rigid aisles’, i.e. inflexible ranges of movement.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GEBHARDT Intralogistics Group‘s catalogsOther GEBHARDT Intralogistics Group products

Warehouse Technology and Systems

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.