- Packing - Handling - Logistics

- Packing and Packaging

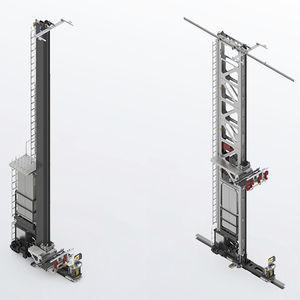

- Handling palletising system

- GEBHARDT Intralogistics Group

Storage system palletising system handlingautomatic

Add to favorites

Compare this product

Characteristics

- Product applications

- handling, for storage systems

- Other characteristics

- automatic

Description

Primarily used as a first-in-first-out system, the principle consists of the intermediate storage of pallets, unit loads and load carriers up to a maximum of 1,500 kg. There are many advantages to this system: Optimum use of space because the lanes do not need to be on a gradient. In addition, the construction has a low overall height. The storage principle ensures that the first item to be stored is the first to leave the warehouse. It is constructed from GEBHARDT accumulating roller conveyors, which ensure functionally reliable continuous operation, as each roller is driven.

Compared to gravity systems, GEBHARDT-live storage offers a significantly higher level of safety for your personnel. This is because the system works without a gradient, which means that brake failure can be ruled out. Without any accumulation pressure, it ensures safe removal of the pallets even if the runners are damaged. Each storage area has a loading side and an unloading side. This keeps distances short and makes work efficient. The warehouse is also infinitely expandable - the flow channels can be 10 m or 100 m long - individually adapted to your requirements.

Benefits

• Optimum use of space because no gradient is needed

• Simultaneous drive of several channels by one motor

• Low roof height

• First-in-First-out principle

• Higher level of safety for your staff - no brake failure

• Short distances and more efficient work

• Unlimited expandability

• Connection to high-performance pallet conveyor technology is possible

• Sorting and feeding with SRM, transfer cars, pallet lifters or forklifts

VIDEO

Catalogs

No catalogs are available for this product.

See all of GEBHARDT Intralogistics Group‘s catalogsOther GEBHARDT Intralogistics Group products

Warehouse Technology and Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.