- Products

- Sheet polyoxymethylene

- GEHR Kunststoffwerk

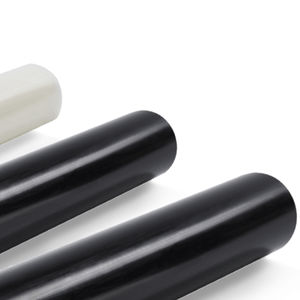

Rod polyoxymethylene GLIDE POM-10PE seriessheet

Add to favorites

Compare this product

Characteristics

- Shape

- rod, sheet

Description

In the group of sliding-modified materials we have included GLIDE-GEHR POM-10PE-TF®, a new material in which the tribological behaviour (friction) has been optimized by incorporating solid lubricants. Thanks to these solid lubricants, we achieve a high wear resistance, a low coefficient of friction and thus a good dry running capability. In addition to the standard features, these plastic materials also have excellent emergency running properties, good damping properties as well as optimized chemical resistance and oxidative stability. Their abrasion behaviour is also positively influenced by the firmly integrated PTFE additive, which is not harmful to health. When machining the previously annealed semi-finished products, thermal overload (plastics are generally poor heat conductors) must be avoided, as otherwise an uneven or scaly surface could form. Due to the incorporated solid lubricant particles, the production of very small surface roughness qualities is only possible to a limited extent.

In joining technology, not only hot plate welding but also adhesive bonding with pressure-sensitive adhesives has proven successful, as the high chemical stability includes resistance to most solvent adhesives. The activation of the surfaces (corona treatment, primer application or etching) enhances the achievable strength. The material is used, for example, in sliding bearings, valve and tap parts. Currently we have rods with a diameter of 20 – 50 mm as well

as sheets with a thickness of 10, 15 and 20 mm in the colour medium blue available in stock.

High wear resistance

Low coefficient of friction

Good dry running capability

Excellent emergency running properties

Catalogs

No catalogs are available for this product.

See all of GEHR Kunststoffwerk‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.