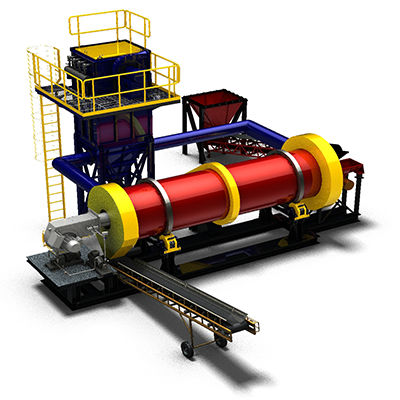

GK’s DUCTA-COOL™ Rotary Dryer and Cooling Drum combines sand cooling, sand and casting separation, and casting cooling in one efficient rotary drum. Gentle tumbling action, coupled with air circulation, creates an evaporative cooling effect to reduce casting temperatures during processing. Sand lumps are broken down as well as blended prior to being screened off at the end of the drum and then returned to the sand system. Put it all together, and you get one rotary dryer machine for multiple functions in an easy to install and maintain equipment package.

FEATURES:

• Sand cooling, sand and casting separation, and casting cooling in one efficient rotary drum.

• Sand is broken down, cooled, and blended, ready to be returned to your sand system.

• Castings are tumbled in a bed of sand to allow cooling and a reduction in casting damage.

• Water addition systems ensure proper evaporative cooling and sand moisture.

• Rotary dryers and drums are available in standard and custom sizes to match your process design and throughput.

• Heavy-Duty construction ensures trouble-free operation for maximum uptime reliability.