Concrete batching mixers, with their various capacities and ease of use, produce compacted ready mixed concrete by mixing aggregate, additives, and cement.

Mixers to be used in concrete plants are chosen according to three main criteria; The capacity, the homogeneity level of the mixture in the specified period and the area to be covered by the mixer in the plant.

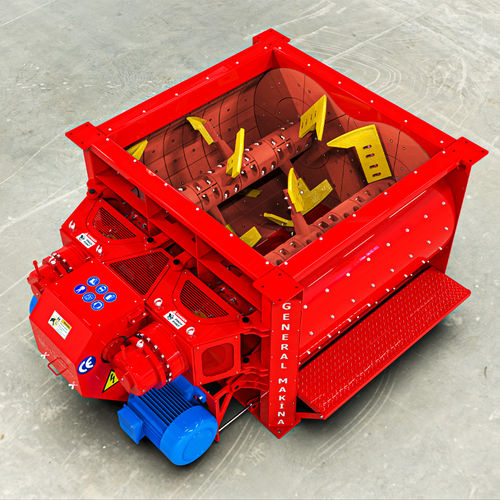

General Makina's Mixer types; Pan type mixer, Single shaft mixer, and Twin Shaft mixer

They can provide the desired full capacity (fixed or mobile)for concrete plants or special concrete preparation projects.

General Makina’s concrete mixing mixers with low investment costs can produce ready-mixed concrete with special capacities between 0.5 m3 and 4.5 m3.

The ready-mixed concrete produced has a high compression ratio and its discharge can be done by means of a single or double cover hydraulic or pneumatic system

In case of power cuts, the discharge covers of the mixture in the mixer can be opened manually

In our mixers, the inner linings are covered with extra wear-resistant Ni-Hard, and the replacement of these liners is possible with a bolted connection system. Casting type can be preferred according to customer demand

Mixer arms and side liners are covered with Hardox

The body strength of the mixers is very robust since they are manufactured with steel construction. In addition, they have an extra layer of paint to protect them from climate-induced corrosion

Pan mixers haves a rotor and its arms have a back reaction system to absorb the pressure against sudden compression. The bearing part of the drive shaft does not touch the concrete so that no probable future leakage or bearing problems would occur