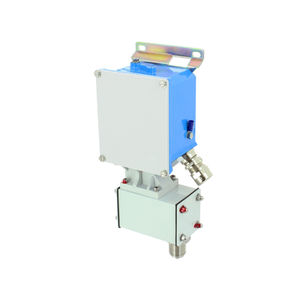

Gas expansion temperature switch F M capillaryadjustableSPDT

Add to favorites

Compare this product

Characteristics

- Heating technology

- gas expansion, capillary

- Type

- adjustable

- Contact type

- SPDT

- Material

- stainless steel, brass

- Protection level

- rugged

- Temperature

Max.: 135 °C

(275 °F)Min.: -50 °C

(-58 °F)

Description

Case: zamak epoxy coated

Sensing element: stainless steel or copper bulb and capillary

Capillary protection: stainless steel armour

Switch: 1 or 2 change over (SPDT) / fix or adjustable deadband

Cable gland: nickel plated brass M16 or JUPITER connector

Features:

» Stainless steel fastening

» Reinforced fixing bracket - Navy type

Pressure variation (or temperature transformed into pressure in accordance with the saturated pressure law [steam pressure]) is transmitted to sensor "S" which activates an internal mechanism comprising a force-balancing system.

The force produced by pressure variation in sensor "S" is balanced by the variation spring. The force applied can be adjusted via a "RS" screw which can be used to set a given operating (or balancing) point.

In the event that the balancing point is exceeded the governor arm will move. Any movements will be detected by contact "C" fitted the end of the stroke.

Pressure variation that requires the contact to be reset in its initial position is referred to as the “deviation”.

The deviation value can be increased by adjusting the variation spring using the wheel labelled"W". Contact trip can only be adjusted upwards. Device services electrical function 34D in the present technical instruction leaflet.

Detectors comprise the following: •A unit comprising 1 or 2 gold plated switches and an operating mechanism. •A pressure sensor (process connection M20x1.5 for versions 1 & 2 ; ½" BSP M for version 3)

Catalogs

No catalogs are available for this product.

See all of GEORGIN S.A.‘s catalogsRelated Searches

- Temperature probe

- Resistance temperature probe

- Digital panel meter

- Industrial pyrometer

- Panel-mount panel meter

- Pt100 temperature probe

- °C pyrometer

- Waterproof thermometer

- Stainless steel pyrometer

- Analog thermometer

- RTD temperature probe

- Threaded temperature probe

- Process panel meter

- Analog temperature probe

- Temperature panel meter

- IP65 pyrometer

- Programmable panel meter

- Bimetallic thermometer

- Dial pyrometer

- Explosion-proof temperature sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.