- Machine-tools

- Finishing Machine

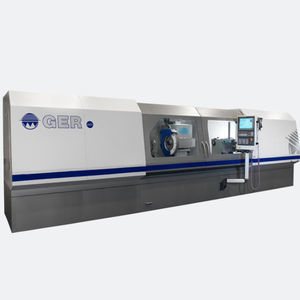

- Cylindrical grinding machine

- GER Maquinas Herramienta S. L. U.

Cylindrical grinding machine C-1.000workpieceuniversalCNC

Add to favorites

Compare this product

Characteristics

- Type

- cylindrical

- Applications

- workpiece

- Structure

- universal

- Control type

- CNC

- Spindle speed

Min.: 10 rpm

(63 rad.min-1)Max.: 1,000 rpm

(6,283 rad.min-1)- Power

5.5 kW, 7.5 kW

(7.48 hp, 10.2 hp)- Distance between centers

1,000 mm

(39 in)

Description

The C-CNC range of grinding machines can be supplied in a number of formats, from a standard cylindrical machine with a single external wheel, right up to a fully universal machine with B axis indexing and multiple wheel combinations..

This range offers excellent flexibility and performance and is ideally suited to smaller components such as punches, shafts and surgical equipment. By introducing the C axis work head rotation control with interpolation the C-CNC machines are also able to carry out non-round and spiral-shaped component grinding.

The C-CNC, as with all GER machines, offers an extensive choice of machine customisation together with a large variety of accessories to enable each machine to be tailored to an individual customer’s production requirements.

Software

The machines are equipped with the latest generation FANUC 0i-TF CNC control, motors and equipment.

• Touch screen programming with user-friendly GER graphic based grinding cycle screens to guide the operator.

• Possibility of grinding different profiles using the profile following cycle.

• Powerful graphic based programming for non-circular profile grinding option (C axis).

• Graphic page for simple adjustment of component taper, camber...

• Wheel dressing is made easy with pre-defined graphic profiles.

• Powerful software allows on-screen graphic visualization and direct input of complex non-standard profiles to be programmed using ISO code.

• USB and Ethernet connections enable programme input and saving.

• Useful feature enables the operator to modify the process during automatic cycle without affecting the original programme.

• Software page application for grinding time calculations.

VIDEO

Catalogs

C series

12 Pages

Other GER Maquinas Herramienta S. L. U. products

CNC CYLINDRICAL & UNIVERSAL GRINDERS

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Flat grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- Automated grinding machine

- Vertical grinding machine

- Internal cylindrical grinding machine

- Universal grinding machine

- High-productivity grinding machine

- High-speed grinding machine

- Gear grinding machine

- 2-axis grinding machine

- Large-size grinding machine

- Heavy-duty grinding machine

- Small workpiece grinding machine

- Metal profile grinding machine

- Grinding machine with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.