- Machine-tools

- Finishing Machine

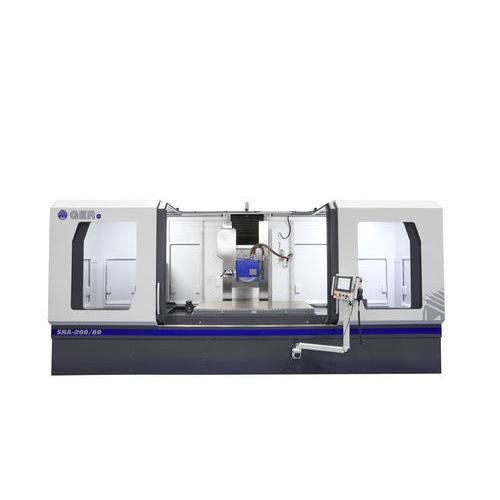

- Surface grinding machine

- GER Maquinas Herramienta S. L. U.

Surface grinding machine SRA seriesworkpieceverticalCNC

Add to favorites

Compare this product

Characteristics

- Type

- surface

- Applications

- workpiece

- Structure

- vertical

- Control type

- CNC

- Other characteristics

- precision

- Power

Min.: 2.2 kW

(2.99 hp)Max.: 46 kW

(62.54 hp)

Description

The SRA-CNC multi-purpose plane surface grinder is a large capacity machine. Both the Y axis vertical movement and the Z axis cross movement are precisely controlled by the CNC.

The machine has on-board storage capacity for up to 6 different programmes.

The CNC control features multiple dressing cycles with automatic wheel diameter compensation and different parameters can be programmed, both for roughing and finish grinding or roughing and finish dressing, which helps to ensure the highest levels of precision and finish.

Software

The machines are equipped with the latest generation Fanuc Oi-MD nano control and equipment.

The simple user-friendly touch screen control uses graphic-based software specially created by GER. The SRA-CNC machine is even easier to use than a conventional grinder and gives the performance and accuracy of a CNC machine without the complex codes. The diamond dressing is table mounted and all dressing cycles include diameter compensation.

The digital servo motor and bass screw system enable the highest levels of precision and productivity. Dressing is made easy with the aid of 9 pre-defined dressing profiles.

MAIN FEATURES:

• Easy component size input and adjustment by touch screen keyboard or by physical position input using “teach-in” mode.

• Dressing on demand with automatic size & speed compensation.

• Independent table and cross axis oscillation movement

• Vertical plunge and pattern grinding.

• Different working parameters for roughing/finish grinding

• Different dressing parameters for roughing/finish dressing

• Angular grinding using interpolation.

• Six programme on-board storage.

• Operator display in different languages.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GER Maquinas Herramienta S. L. U.‘s catalogsRelated Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Flat grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- Automated grinding machine

- Vertical grinding machine

- Internal cylindrical grinding machine

- Universal grinding machine

- High-productivity grinding machine

- High-speed grinding machine

- Gear grinding machine

- 2-axis grinding machine

- Large-size grinding machine

- Heavy-duty grinding machine

- Small workpiece grinding machine

- Metal profile grinding machine

- Grinding machine with rotary table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.