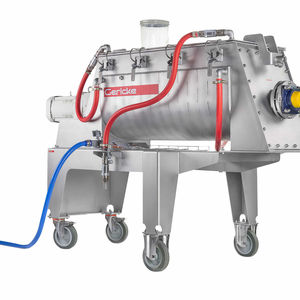

Twin-shaft mixer GMS Multiflux® paddlebatchfor liquids

Add to favorites

Compare this product

Characteristics

- Technology

- paddle

- Batch/continuous

- batch

- Product type

- for liquids, solid

- Configuration

- horizontal

- Other characteristics

- twin-shaft, hygienic

- Applications

- for the food industry, laboratory

- Capacity

Max.: 4,000 l

(1,056.69 gal)Min.: 100 l

(26.42 gal)- Flow

70,000 l/h

(18,492.04367 us gal/h)

Description

Superb homogeneity, gentle and hygienic

The GERICKE GMS Multiflux® batch mixer achieves a maximum degree of homogeneity and preserves high-quality ingredients during the mixing process. When the mixing of fragile products, the efficient distribution of micro ingredients, the optimal dispersion of liquids onto particles or the highest hygienic requirements are your challenges, then the GMS Multiflux batch blender is your best choice.

Mixers with extractable drive

Watch these videos to see how our mixers meet the highest standards for access, cleanability and hygienic design.

Short mixing time

Gericke batch mixers GMS Multiflux® form a mechanical fluidised zone by using two horizontally arranged superimposed counter-rotating mixing tools. This design enables extremely high radial and axial transfer rates, resulting in the highest homogeneity. The mixer operates at the optimal Froude Number of 1.1, where the centrifugal forces exceed gravity forces. Mixing is realised efficiently in short cycle times but with gentle handling for sensitive products.

Gericke GMS mixers can produce up to 16 mixing cycles per hour and are available in sizes of 100 to 4000 litres (useable volume) per batch. The standard cantilevered design of the GMS mixer allows optimal access for the operator via a huge swiveling front door. This door gives full access to the mixing chamber for inspection and cleaning.

Highly flexible

For dispersion of viscous liquids or deagglomeration of lumps, fast rotating dispersion tools can be integrated into the front door.

VIDEO

Catalogs

COMPETENCE IN MIXING

7 Pages

Product overview

16 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.