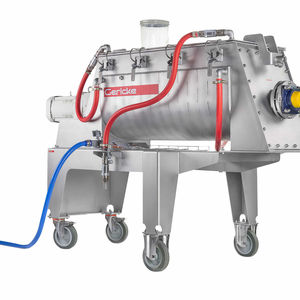

Batch blender for the pharmaceutical industry GBMfor solidslow-capacitycontinuous

Add to favorites

Compare this product

Characteristics

- Product

- for solids

- Applications

- for the pharmaceutical industry

- Other characteristics

- continuous, batch, low-capacity, low-flow

- Flow rate

Max.: 20 kg/h

(44.1 lb/h)Min.: 0 kg/h

(0 lb/h)

Description

Blending for continuous manufacturing of solids

The Gericke Mini Batch Blender is a semi-continuous approach to make continuous manufacturing suitable for low dosage, low volume, highly potent products. It combines advantages of the traditional batch and true continuous manufacturing processes to generate a simplified system. Choose between the integrated Gericke Formulation Skid GFS or standalone equipment for early phase development.

Advantages of our Mini Batch Blenders

• Maximal mixing homogeneity (even with very low API concentrations)

• Minimal batch sizes < 1 – 3 kg

• No start-up losses

• Simple feeder start up

• Simple material tracking no RTD modelling

• Simple integration of PAT, even Raman feasible

• Simple control strategy

• High containment, Wash-in-Place WIP

Catalogs

COMPETENCE IN MIXING

7 Pages

Product overview

16 Pages

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Stainless steel agitator

- Horizontal grinding mill

- In-line mixer

- Food lump breaker

- Powder blender

- Automatic dosing unit

- Horizontal blender

- Mixer-dispenser

- Agitator for the pharmaceutical industry

- Paddle blender

- Solid dispensing system

- Dosing unit for the food industry

- Compact agitator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.