- Products

- Catalogs

- News & Trends

- Exhibitions

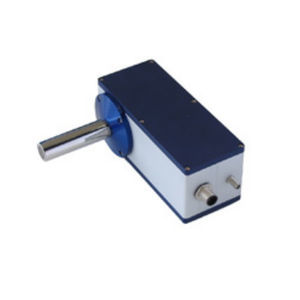

Electrochemical oxygen sensor getOtwo 3207USBModbus RTUreal-time

Add to favorites

Compare this product

Characteristics

- Technology

- electrochemical

- Output

- USB, Modbus RTU

- Other characteristics

- real-time

Description

water analysis

beverage analysis

concentration measurements, e.g. in slurries, oils ...

monitoring of processes of oxidation

monitoring of filling process

12mm shaft out diameter

inert POM housing

2 independent oxygen measurement channels in one sensor

RS485 with Modbus RTU and 2x 0-5VDC (or 2x 4(0)-20mA for getOtwo 3207 i)

IP68 / NEMA 6

120 mm shaft length

Spot is pre-calibrated

The state-of-the-art oxygen sensor getOtwo 3207 is based on the principle of fluorescence quenching.

Usual standard electrodes can be replaced due to getOtwo's shaft having an outer diameter of only 12mm.

Long tool life at minimized maintenance efforts guarantee low operating expenses at high measuring safety

The first and only system with two separate measurement channels for real-time referencing built into a shaft with 12 mm out diameter

Plug-in the sensor directly in fixtures for pH or electrochemical oxygen probes

Monitoring of the health status and the status of the sensitive element

No corrosion of housing by reason that it is POM

Sensitive element placed in robust cap for easy replacement

No fragile oxygen membrane or problems coming from electrolyte

No oxygen consumption, no cross sensitivity to e.g. CO2, H2S, flow

Less maintenance

Temperature measurement implemented

IP67 / NEMA 6

Versatile connection via RS485 and Modbus RTU or Sentronic protocol and 2x 0-5VDC (or 2x 4(0)-20mA for getOtwo 3207 i) and an additionally USB converter

Separate trigger and alarm channel

Windows based PC-Software inclusive

Related Searches

- Concentration analyser

- Monitoring analyser

- Liquids analyser

- Dust analyzer

- Spectrometer

- Water analyser

- Calibration analyser

- Oxygen meter

- Moisture analyser

- Compact spectrometer

- Process spectrometer

- Electrochemical oxygen sensor O2

- Measurement spectrometer

- PH analyzer

- Process probe

- Fast spectrometer

- USB spectrometer

- Infrared spectrometer

- Protein analyser

- Food spectrometer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.