- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

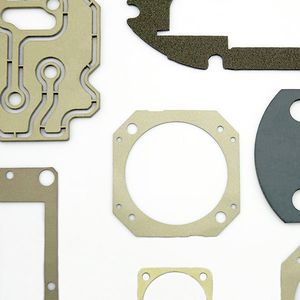

EMC shielding gasket GT1000flatrectangularelastomeric

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Configuration

- rectangular

- Material

- elastomeric, silicone

- Application

- for automotive applications, EMC shielding, electronic equipment, for aerospace applications, for medical applications, for aeronautical applications, for telecommunications equipment, EMC conduit, for the electronics industry

- Temperature limit

Min.: -55 °C

(-67 °F)Max.: 125 °C

(257 °F)- Shore A hardness

82 unit

Description

Electromagnetic compatibility (EMC) is an essential feature for all electronic equipment. The function of a electrically conductive elastomer gasket is to maintain electrical continuity in the EMC shielding. The conductive filler used for our conductive silicone seals is adjusted according to the electromagnetic performance required and the environment in which your equipment is located.

The conductive particles (10 to 40 microns) that make up the filler of our conductive mixes (between 60 and 80% filler ratio) allow you to acquire optimal EMC shielding.

Our electrically conductive elastomers are developed in every respect by our chemical engineers. From the selection of raw materials to the final transformation, they create specific formulations for each request and master all the development processes and procedures.

This mastery allows us to define the ideal material according to your equipment and your specifications, in order to offer you a bespoke conductive solution adapted to your needs.

The three guarantees of our conductive silicone seals

Electrical continuity performance

Mechanical performance

Extreme temperature resistance

Discover our range of conductive

materials

Getelec develops and manufactures silicone- and fluorinated silicone-based conductive solutions filled with conductive particles such as silver-plated copper, silver, silver-plated nickel, graphite nickel, aluminium nickel, silver-plated aluminium, treated aluminium, carbon and silver-plated glass beads to guarantee optimal galvanic and electromagnetic compatibility.

Catalogs

Conductive silicone GT1000

1 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.