- Machine-tools

- Machining Center

- 3-axis CNC milling machine

- GF Machining Solutions

3-axis CNC milling machine MILL P 900verticalHSK A-63HSK-E50

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- HSK A-63, HSK-E50

- Number of tool stations

- 30 tools, 60 tools

- Applications

- for the mold industry

- Other characteristics

- high-productivity

- X travel

900 mm

(35.43 in)- Y travel

600 mm

(23.62 in)- Z travel

450 mm

(17.72 in)- Rotational speed

20,000 rpm, 36,000 rpm

(125,664 rad.min-1, 226,195 rad.min-1)- Power

33 kW, 36 kW

(44.87 hp, 48.95 hp)- Work feed X-axis

30,000 mm/min

(20 in/s)- Work feed Y-axis

30,000 mm/min

(20 in/s)- Work feed Z-axis

30,000 mm/min

(20 in/s)- Table load capacity

1,000 kg

(2,205 lb)- Weight

12,000 kg

(26,455.47 lb)- Overall length

2,066 mm

(81.3 in)- Overall width

5,318 mm

(209.4 in)- Overall height

3,102 mm

(122.1 in)

Description

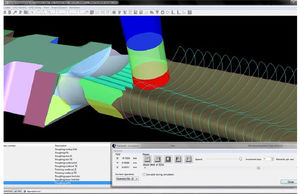

With its robust portal structure featuring high dynamic stiffness, this solution is especially designed for mold, die and part producers who are looking for the best surface quality and very high positioning and contour accuracy. With the machine’s one-touch process, manufacturers can experience roughing and finishing performance on one single machine. Thanks to the machine optimum ergonomics manufacturers can easily load workpieces up to 1,000 kg manually through the broad front door. Moreover, with its integrated Automation from the back through the gantry and a capacity of up to 280 kg, manufacturers’ second and third shift productivity is fully covered at a lower cost. With a symmetrical gantry design, a polymer concrete structure, and integrated cooling management that includes water cooling through the machine base and Intelligent Thermal Control (ITC), the MILL P 900 provides high thermal stability around the clock.

Minimize reworking time

Improve your processes, minimize your manual operation, and reach best cutting conditions and perfect surface finishing—no polishing needed.

Get your parts faster

Achieve efficient roughing and finishing operations on this machine thanks to the 20,000 rpm, 120 Nm Step-Tec Spindle.

Increase your productivity

Let the machine work as much as possible. Take on a second or third shift while lowering your costs, thanks to integrated Automation from the back.

100% higest accuracy

Thank to temperature controlled machine base, Spindle and other key components.

50% more productivity

Integrated automation and professional chip management

VIDEO

Catalogs

Mikron MILL P 900

26 Pages

Related Searches

- CNC machining center

- GFMS - GF Machining Solutions CNC milling machine

- 5-axis CNC machining center

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Rigid CNC machining center

- GFMS - GF Machining Solutions precision CNC milling machine

- Horizontal CNC machining center

- GFMS - GF Machining Solutions electrical discharge machine

- CNC machining center with rotary table

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Universal CNC machining center

- CNC EDM

- GFMS - GF Machining Solutions precision electrical discharge machine

- High-performance CNC milling machine

- Die sinking EDM

- 32 tools CNC machining center

- Rigid CNC milling machine

- 120 tools CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.