- Machine-tools

- Machining Center

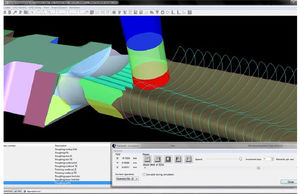

- 5-axis CNC milling machine

- GF Machining Solutions

5-axis CNC milling machine MILL E seriesverticalBT 40HSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Spindle mount

- BT 40, HSK A-63

- Number of tool stations

- 30 tools, 60 tools, 120 tools, 170 tools

- Applications

- heavy-duty

- Other characteristics

- high-performance

- X travel

500 mm, 700 mm

(19.69 in, 27.56 in)- Y travel

450 mm, 600 mm

(17.72 in, 23.62 in)- Z travel

400 mm, 500 mm

(15.75 in, 19.69 in)- Rotational speed

12,000 rpm, 20,000 rpm

(75,398 rad.min-1, 125,664 rad.min-1)- Work feed X-axis

30,000 mm/min

(20 in/s)- Work feed Y-axis

30,000 mm/min

(20 in/s)- Work feed Z-axis

30,000 mm/min

(20 in/s)- Table load capacity

300 kg, 450 kg, 500 kg

(661 lb, 992 lb, 1,102 lb)- Weight

6,030 kg, 8,060 kg

(13,293.87 lb, 17,769.26 lb)- Overall length

4,600 mm, 5,007 mm

(181.1 in, 197.1 in)- Overall width

6,590 mm, 6,830 mm

(259.4 in, 268.9 in)- Overall height

2,600 mm, 2,890 mm

(102.4 in, 113.8 in)

Description

The range of solutions is a second-generation successor to the HEM U range. It brings greater machining capacity and better machining performance to a more robust machine base. With the large swivel range from -65° to + 120° and the ability to load heavy parts up to 450 kg onto the tilting, swiveling table, these solutions U allows users to manufacture a wider range of parts and tools than any other machine currently on the market. It is based on a stiff and stable C-frame construction made out of cast iron. Thanks to large guideways, a double side-supported rotary table and an optimum chip removal rate, this machine delivers quality on parts and reliable operations. Whether you are a job shop or a part producer, these machines are the right solutions to help you tackle the many different requirements coming from the automotive, energy and power generation, and general mechanics industries.

Unleash your business

Unleash your business with these solutions for 3+2 and full simultaneous Milling. Save time, costs and operator error—whatever your machine choice.

Unleash your best

Produce with 100% quality and unleash your best with this affordable, high-efficiency solution.

+ 10% heavy-duty, precise and dynamic Milling

450 kg load on the table Stepwise adjustment of the dynamic. Strong motor Spindle with 120 Nm

24/7 billable autonomy

Integrated Automation with GF Machining Solutions' WPC 10. Various pallets (Dynafix/Delphin) are available as standard.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GF Machining Solutions‘s catalogsRelated Searches

- CNC machining center

- GFMS - GF Machining Solutions CNC milling machine

- 5-axis CNC machining center

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Rigid CNC machining center

- GFMS - GF Machining Solutions precision CNC milling machine

- Horizontal CNC machining center

- GFMS - GF Machining Solutions electrical discharge machine

- CNC machining center with rotary table

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Universal CNC machining center

- CNC EDM

- GFMS - GF Machining Solutions precision electrical discharge machine

- High-performance CNC milling machine

- Die sinking EDM

- 32 tools CNC machining center

- Rigid CNC milling machine

- 120 tools CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.