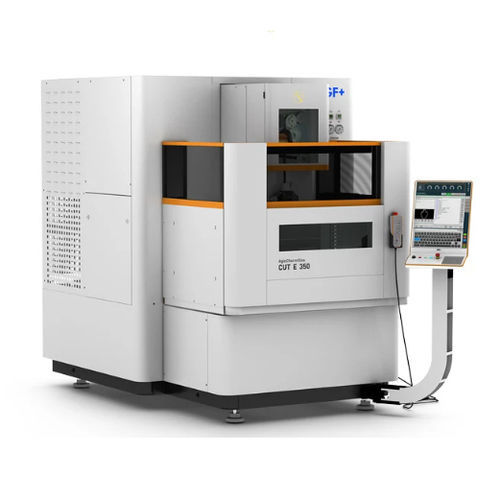

The AgieCharmilles CUT E Series puts efficiency at the touch of your finger with a smart, easy-to-use human-machine interface (HMI) and onboard technologies that streamline your job setup. Thanks to the digital Intelligent Power Generator (IPG), cutting speed and surface finish are improved.

High performance with a complete range of technologies

Extremely high removal rates and low hourly running costs are possible with cheap brass wires (speed technology). The generator has a complete range of technologies including all materials needed for your workshop.

High-accuracy T-type mechanics

The T-type base frame permits the loading of large and heavy work pieces without affecting accuracy. The compact and rigid machine structure guarantees good positioning accuracy and highly repeatable results.

1,000 kg part weight

Thanks to the T-shaped base, large and heavy workpieces up to 1,000 kg can be easily loaded and unloaded.

19-inch touch screen

Gives you a clear view of the process management. Job preparation, monitoring of the current job, and various functions are available in a single view.

30% less floor space

Significantly more compact that its predecessor, this machine consumes only about four square meters, allowing its efficient integration into your workshop.

2,000 hours

Maintenance every 2,000 machining hours is recommended for the optimal functionality, reliability and precision of your equipment.

Power your performance

Your efficient production is at the heart of the modern Intelligent Power Generator (IPG). Its onboard technologies boost cutting speed, precision and surface quality to satisfy your customers and put you ahead of your competitors.