- Machine-tools

- Machining Center

- 3-axis CNC milling machine

- GF Machining Solutions

3-axis CNC milling machine MILL E seriesverticalBT 40HSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- BT 40, HSK A-63, ISO 50, BT 50

- Number of tool stations

- 24 tools, 30 tools, 40 tools, 60 tools

- Applications

- for the mold industry

- Other characteristics

- high-performance, compact, high-precision

- X travel

Min.: 600 mm

(23.62 in)Max.: 2,000 mm

(78.74 in)- Y travel

Min.: 500 mm

(19.69 in)Max.: 900 mm

(35.43 in)- Z travel

Min.: 540 mm

(21.26 in)Max.: 800 mm

(31.5 in)- Rotational speed

6,000 rpm, 10,000 rpm, 12,000 rpm, 16,000 rpm, 20,000 rpm

(37,699 rad.min-1, 62,832 rad.min-1, 75,398 rad.min-1, 100,531 rad.min-1, 125,664 rad.min-1)- Work feed X-axis

15,000 mm/min, 20,000 mm/min, 24,000 mm/min, 32,000 mm/min, 40,000 mm/min

(10 in/s, 13 in/s, 16 in/s, 21 in/s, 26 in/s)- Work feed Y-axis

15,000 mm/min, 20,000 mm/min, 24,000 mm/min, 32,000 mm/min, 40,000 mm/min

(10 in/s, 13 in/s, 16 in/s, 21 in/s, 26 in/s)- Work feed Z-axis

15,000 mm/min, 20,000 mm/min, 24,000 mm/min, 32,000 mm/min, 40,000 mm/min

(10 in/s, 13 in/s, 16 in/s, 21 in/s, 26 in/s)- Table load capacity

Min.: 800 kg

(1,764 lb)Max.: 3,000 kg

(6,614 lb)- Weight

Min.: 4,800 kg

(10,582.19 lb)Max.: 20,600 kg

(45,415.23 lb)- Overall length

Min.: 2,240 mm

(88.2 in)Max.: 4,680 mm

(184.3 in)- Overall width

Min.: 3,338 mm

(131.4 in)Max.: 4,471 mm

(176 in)- Overall height

3,032 mm

(119.4 in)

Description

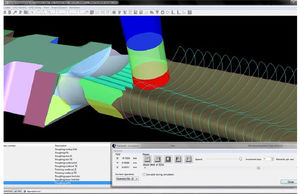

The vertical, three-axis Mikron MILL E 800 and Mikron MILL E 1200 sets standards in VMC category. Its value are robustness, compactness and user friendliness. The perfect harmonization of both machining performances and stability is the fruit of long development experience of our engineers. The results is efficient precision production equipment with an irreproachable operation in any situation.

Easy and fast set up with full access

Get an optimal view and access to your workpiece to speed up setup time and extend your running time even without automation. Experience effortless crane loading, thanks to a "1+1/2"-door systems for maximum table and workpiece access, and large windows on all sides for an unlimited view of the workpiece.

Low downtime due to quality components

Say goodbye to unplanned downtime, due to our high-quality standards. Ensure your part quality and your on-time delivery with a solution engineered—and tested—for your success embedded high-quality powered components.

Fast delivery for a quick ROI

Get faster return on investment with our fast delivery of our most popular machine configurations. Go from your investment decision to producing your first parts within two weeks thanks to our fast European stock. Choose the single-source solution provider who puts you on the fast path to success.

Stiff and compact design for 100% flexibility

The Mikron MILL E series offers spectacular, reliable performance in conventional three axis application alike thanks to well-known and proven components brought together in a highly efficient package built for performance.

Catalogs

No catalogs are available for this product.

See all of GF Machining Solutions‘s catalogsRelated Searches

- CNC machining center

- GFMS - GF Machining Solutions CNC milling machine

- 5-axis CNC machining center

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Rigid CNC machining center

- GFMS - GF Machining Solutions precision CNC milling machine

- Horizontal CNC machining center

- GFMS - GF Machining Solutions electrical discharge machine

- CNC machining center with rotary table

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Universal CNC machining center

- CNC EDM

- GFMS - GF Machining Solutions precision electrical discharge machine

- High-performance CNC milling machine

- Die sinking EDM

- 32 tools CNC machining center

- Rigid CNC milling machine

- 120 tools CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.