- Machine-tools

- Machining Center

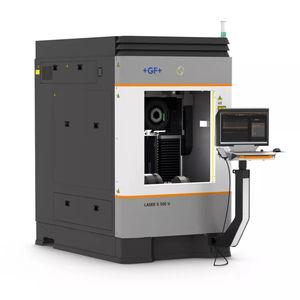

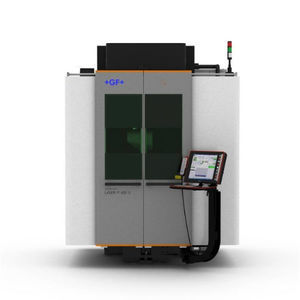

- Laser micro-machining machine

- GF Machining Solutions

Laser micro-machining machine MLTCmedicalfor tubescutting

Add to favorites

Compare this product

Characteristics

- Type

- laser

- Applications

- medical, for tubes

- Associated functions

- cutting

- X travel

280 mm

(11.02 in)- Y travel

20 mm

(0.79 in)- Z travel

24 mm

(0.94 in)- Power

40 W

(0.05 hp)- Weight

2,300 kg

(5,070.63 lb)

Description

Simplify the complex machining processes in cutting tubes for medical applications

Achieve success in the medical device industry and other applications, thanks to the ultrafast MLTC Laser tube-cutting platform. Quickly and accurately machine complex features in metal and polymer tubes with high precision.

Maintain consistently stable quality

Unique granite-based mechanical design. Get the enhanced productivity that comes from achieving high and constant speed, thanks to this solution’s core design principle: short structural loops for a low center of gravity. Granite delivers thermal stability due to its low thermal expansion coefficient.

One process to improve in quality, efficiency and flexibility

Experience the perfect combination of precision and flexibility in one Laser solution and machine even the most complex designs in a single setup—all with unmatched part quality and an optimized workflow.

Reduce scrapped parts

Easily handle small, thin-walled parts and avoid the risk of scrapped parts, thanks to our smart clamping tool. This innovative concept manages and clamps your parts without damage.

Femtosecond Laser process

Minimize material lost during the machining process, achieve superior, burr-free surface finishing, and get dimensional control—all thanks to femtosecond Laser pulses allowing clean material ablation.

Zero heat-affected zones (HAZ)

Achieve perfect cuts in seconds and produce medical devices in a single process thanks to the reduced heat-affected zone (HAZ) enabled by femtosecond Laser. Engrave a wide range of materials—burr-free.

Catalogs

Related Searches

- CNC machining center

- GFMS - GF Machining Solutions CNC milling machine

- 5-axis CNC machining center

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Rigid CNC machining center

- GFMS - GF Machining Solutions precision CNC milling machine

- Horizontal CNC machining center

- GFMS - GF Machining Solutions electrical discharge machine

- CNC machining center with rotary table

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Universal CNC machining center

- CNC EDM

- GFMS - GF Machining Solutions precision electrical discharge machine

- High-performance CNC milling machine

- Die sinking EDM

- 32 tools CNC machining center

- Rigid CNC milling machine

- 120 tools CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.