- Production Machines

- Additive Manufacturing, 3D Printing

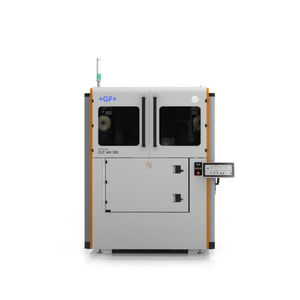

- Metal 3D printer

- GF Machining Solutions

Metal additive manufacturing machine DPM Factory 500industrial

Add to favorites

Compare this product

Characteristics

- Materials to be printed

- metal

- Applications

- industrial

- Layer thickness

Min.: 2 µm

Max.: 200 µm

- Weight

8,232 kg

(18,148.45 lb)

Description

Discover our game-changer for the AM world

The DMP Factory 500 is a workflow-optimized metal 3D printing solution for massive scalability, repeatable high-quality parts, high throughput and low TCO, producing parts of up to 500 x 500 x 500 mm in size. Engineered using 3D Systems’ proven precision metal additive technology, along with GF Machining Solutions’ technical and industrial knowledge, and the precision System 3R clamping systems, the DMP Factory 500 solution is a fully integrated, streamlined metal AM platform

Build higher quality large parts

Metal 3D printing emerged as a technology best suited for producing small, intricate metal parts. As part sizes go up, achieving consistent, high quality parts becomes a challenge that requires deep expertise and clever engineering solutions.

Lower Total Cost of Ownership

TCO and final per-part costs are key factors. The modularity of the DMP Factory 500 solution allows manufacturers to define a factory setup that is tailored to their application and capacity requirements and maximizes the use of each module.

Simplify process workflow

An efficient factory is streamlined from end to end. With extensive experience in the production environment, our engineers have packaged their production workflow expertise into functional modules that enable maximum uptime and efficiency.

Scale in a factory environment

Setting up an AM factory relies on scalable solutions to adjust to increased demand. DMP Factory 500 is designed to start and grow a factory setup, with the flexibility to configure the function-specific modules to your specific requirements.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GF Machining Solutions‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.