- Machine-tools

- Machining Center

- 5-axis CNC milling machine

- GF Machining Solutions

5-axis CNC milling machine Turbomill seriesverticalHSK A-63HSK-80-A

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Spindle mount

- HSK A-63, HSK-80-A

- Number of tool stations

- 40 tools, 60 tools, 32 tools

- Associated functions

- engraving, chamfering

- Applications

- for turbine blades

- Other characteristics

- high-performance, compact, rigid, for production

- Rotational speed

16,000 rpm, 19,000 rpm, 20,000 rpm

(100,531 rad.min-1, 119,381 rad.min-1, 125,664 rad.min-1)- Power

25 kW, 28 kW

(33.99 hp, 38.07 hp)

Description

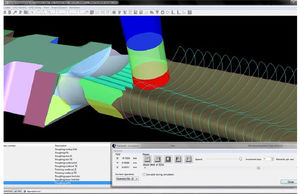

The Turbomill is designed for the production of airfoils with 5-axis simultaneous machining technology. Extensive manufacturing experience and CAM programming to suit application specific requirements in technology and service are provided by Liechti – a team of specialist in the production of turbomachinery components for aerospace and power generation.

Highest profile accuracy and trailing edge quality in shortest machining time

Complete machining in one setup, including bar feeding, five-axis Milling, turning, root machining, threading, chamfering, engraving and brushing

Rigid, compact layout of all axes for high jerk machining

Turn-key solution including specialized TurboSoft plus CAM software

The solution for production turbine blades

Roughing and finishing of airfoil, hub and shroud in 1 setup as well as probing and adaptive machining of mid-span, chord and further areas of turbine blades.

Uncompromising for airfoils

High-dynamic machining around the entire airfoil for better quality results and longer tool life.

Turbomill 500g

A high-performance machine, designed for precise airfoil manufacturing. Powerful yet compact, the Turbomill 500g provides high dynamics, stable machining at high speed and high accuracy.

Improve your overall equipment efficiency

Reduce your cycle times

Increase your quality rate

Reduce your maintenance costs

One single source provider

High productivity with g-technology

Reduce your cycle times up to 30%. Keep the profile feed rate higher, especially around the leading and trailing edges.

Catalogs

No catalogs are available for this product.

See all of GF Machining Solutions‘s catalogsRelated Searches

- CNC machining center

- GFMS - GF Machining Solutions CNC milling machine

- 5-axis CNC machining center

- GFMS - GF Machining Solutions vertical CNC milling machine

- 3-axis CNC milling machine

- Rigid CNC machining center

- GFMS - GF Machining Solutions precision CNC milling machine

- Horizontal CNC machining center

- GFMS - GF Machining Solutions electrical discharge machine

- CNC machining center with rotary table

- 5-axis CNC milling machine

- GFMS - GF Machining Solutions high-precision CNC milling machine

- Universal CNC machining center

- CNC EDM

- GFMS - GF Machining Solutions precision electrical discharge machine

- High-performance CNC milling machine

- Die sinking EDM

- 32 tools CNC machining center

- Rigid CNC milling machine

- 120 tools CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.