Programming software GO Solid TurningCADmodelinginteroperability

Add to favorites

Compare this product

Characteristics

- Function

- programming, CAD, modeling, interoperability

- Applications

- machining

- Type

- automated

- Other characteristics

- NX

Description

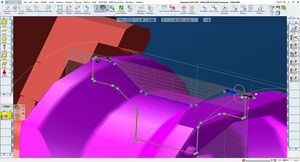

GibbsCAM’s cost-effective suite of solids-based options provide a more complete representation and enable more intuitive modeling and advanced machining capabilities for today’s solid and surface models.

Create ultra-efficient part programs with gouge-free toolpaths using GibbsCAM’s integrated advanced machining capabilities. Programming efficiency is significantly enhanced with highly automated multi-tool machining methods.

Powerful Solid Modeling

Whether you import solid models from a CAD system, create your own from scratch, or modify an imported solid to create a manufacturable version, GibbsCAM GO Solid Turning provides a full range of solid modeling functionality with advanced functionality like history trees to support you. And its industry-leading ease-of-use makes working with solids straightforward and easy-to-understand. With its powerful solid modeling tools, you can take full advantage of solid modeling technology.

Importing and Repairing Surface Models

Even with the transition to solids, CAD systems still generate surface models that must be imported and machined. With GibbsCAM GO Solid Turning, you can read in surface models and then repair any problems that you encounter with a broad range of surface modeling tools. And you can create your own surfaces for machining. If you still work with surface models, GibbsCAM GO Solid Turning can still cut your jobs and provide a great migration path to solids-based machining.

CAD Import

Import Parasolids, ACIS/SAT, STEP® and VDA models, and also directly from well-known CAD systems such as Solid Edge®, SOLIDWORKS®, and Inventor®. Options are available to extend CAD Interoperability for PTC, CATIA and NX.

Catalogs

No catalogs are available for this product.

See all of GibbsCAM‘s catalogsRelated Searches

- Automation software solution

- Process software solution

- Computer-aided design software

- Control software solution

- 3D software solution

- Interface software

- Quality software

- Simulation software

- Programming software

- Automated software

- Machine software

- EDM software

- 2D software

- Creation software

- Modeling software

- CAM software

- Flow software

- CAD/CAM software

- Editing software

- Milling software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.