Quality software Sandvik Coromant OptiThreading™controlcuttingmachine

Add to favorites

Compare this product

Characteristics

- Function

- quality, control, cutting

- Applications

- machine, for turning

Description

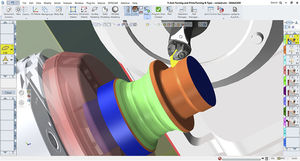

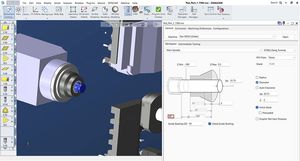

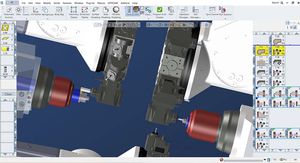

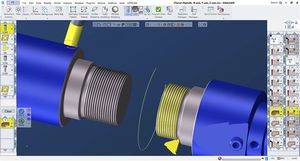

GibbsCAM’s new turning strategy for OptiThreading™ enables controlled chip breaking to eliminate long stringy chips that can damage a component’s surface and interfere with the cutting zone. It is just as suitable for simple threads as it is for cutting complex thread profiles, in high-strength alloys or exotic materials.

Using cutting data from CoroPlus® Tool Library, OptiThreading™ enables users to develop optimized thread turning tool paths that specifically overcome the challenge of chip control with these operations. This is achieved by specialized GibbsCAM tool paths that use controlled, oscillating movements in and out of the cut for interrupted cuts on all passes except the last one. The result is controlled chip control for improved component quality, faster cutting speeds and less manual work by reducing the need to manually clear long chips during the machine run cycle.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GibbsCAM‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- Design software solution

- 3D software solution

- Interface software

- Quality software

- Simulation software

- Visualization software solution

- Programming software

- Automated software

- Machine software

- EDM software

- Creation software

- 2D software

- Modeling software

- Safety software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.