- Products

- Catalogs

- News & Trends

- Exhibitions

3D inspection machine GMSfor large partsfor gearssurface

Add to favorites

Compare this product

Characteristics

- Technology

- 3D

- Applications

- surface, for gears, for large parts

- Sector

- industrial

- Other characteristics

- automated, measurement

Description

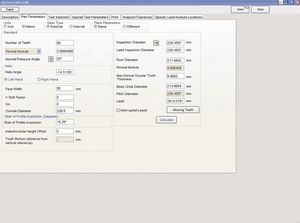

Gleason Metrology Systems offers a complete line of gear metrology systems for the inspection of medium and large-sized gears and shafts up to 3,000 mm in diameter and lengths up to 2,500 mm. With its wide array of options, the GMS® Series supports any kind of inspection requirement, including surface measurement, Barkhausen Analysis, CMM capability and gear tool inspection.

Helix angle 0 to 90°

Module range 0.3 to 32 mm

Workpiece length, max.* 2,500 mm

Workpiece diameter, max. 3,000 mm

Become Versatile

The GMS Series is equipped with high accuracy 3D scanning probes with a broad range of styli, including a stylus calibration library and optional automatic probe changer.

Measure Surfaces

GMS offers a wide range of surface roughness measurements, meeting the most common roughness parameters as defined in DIN, ISO, ANSI and more.

Employ Barkhausen

Inspect gears and other parts for surface hardness as well as residual and compressive stresses.

Get CMM Capabilities

Enjoy 3D measurement and analysis capabilties typically performed by a CMM.

Measure Gear Tools

GMS systems handle inspection of many gear cutting tools including hobs, shaper and Power Skiving cutters, stick blades and shaving tools. Depending on size, even most broaches and rack cutting tools are accommodated.

Be Fully Compatible

GAMATM 3.1 or 3.2 Applications and Control Software is fully compatible with Windows and connects easily to customers' servers. GAMA includes SPC data acquisition software and Gleason Connect® Global Support Services.

Catalogs

Related Searches

- Inspection machine

- Automatic inspection machine

- Industrial inspection machine

- Optical inspection machine

- Measurement inspection machine

- Surface inspection machine

- Automated inspection machine

- 3D inspection machine

- CT inspection machine

- Gear inspection machine

- Semi-automatic inspection machine

- Cutting tool inspection machine

- Large part inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.