- Products

- Catalogs

- News & Trends

- Exhibitions

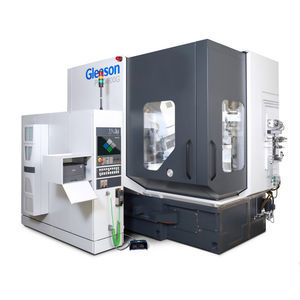

CNC gear-hobbing machine Genesis 280CD

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

Description

Two chamfer technologies are available on one single platform: Chamfer Hobbing, ideal for high volume automotive and light truck applications, including final drive ring gears and shafts; and Fly Cutter Chamfering, delivering exceptional flexibility for lower volume, small lot jobber applications. The Genesis 280CD Gear Chamfering Machine is available as standalone version, or as fully integrated hobbing and chamfering machine, the Genesis 280HCD.

Workpiece diameter, max. 280 mm

Module, nominal 5 mm

Axial slide travel, max. 300 mm

Two Processes on One Plattform

When an application calls for more chamfering flexibility, Fly Cutter Chamfering is the method of choice. Chamfer Hobbing is the idealy solution for medium and high volume.

High Volume Chamfer Hobbing with Minimum Tool Cost per Workpiece

Gleason Chamfer Hobbing process offers tool shifting, delivering increased tool life and resulting in the very low tool cost-per-piece: just 1 to 2 cent for a typical automotive workpiece.

Flexible Fly Cutter Chamfering for Smaller Lots and Prototyping

Fly Cutter Chamfering is a very universal process. A single tool can be used for different modules, pressure angle, and number of teeth. With just a few, standard, inexpensive and easily sourced base bodies and respective blade sets, users can cover a wide range of gears to be chamfered.

Automation Options

Automation solution by Gleason Automation Systems with robot loading, optional automation solution by customer supplied robot possible.

Disc- and Shaft-Type Workpieces

The Genesis 280CD offers optional a CNC tailstock for shaft-type workpieces and clamping of cluster gears.

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogsRelated Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Precision CNC milling machine

- High-precision CNC milling machine

- Gear-hobbing machine

- CNC gear-cutting machine

- CNC gear-shaping machine

- Gear-shaping machine

- High-power CNC milling machine

- Vertical gear-hobbing machine

- Horizontal gear-hobbing machine

- Gear shaving machine

- Vertical gear-shaping machine

- CNC gear shaving machine

- Horizontal gear shaving machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.