- Products

- Catalogs

- News & Trends

- Exhibitions

Metrology system 300GMS nano

Add to favorites

Compare this product

Description

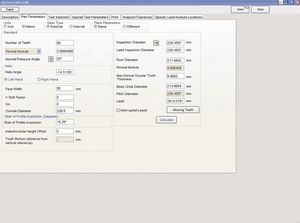

leason 300GMS® nano Gear Metrology System combines all the latest inspection capabilities into a single, compact platform for the complete inspection of gears up to 300 mm in diameter and shafts up to 500 mm in length, fine pitch gears as small as .2 module. Repeatability and reliability exceed VDI/VDE2612 standards for form measurement up to factor 5.

Helix angle

- 0 to 90°

Module range - 0.2* to 18 mm

Workpiece length, max.** - 500 mm

Workpiece diameter, max. - 300 mm

Evaluate Waviness on Submicron Level and Analyze Gear Noise

Measure submicron surface finish with a skidless probe, analyze waviness for profile, lead and pitch, including noise analysis with sophisticated software tools.

Resist Thermal Deviations and Vibrations

Highly accurate precision guides, laser-mapped with Invar scales and an air-cushioned, no slip-stick table create the reference in precision inspection. Optionally, choose the GMSP Series with its patented machine base with super-dampening by air-cushions.

Become Versatile with Smart APC

The GMS Series is equipped with high accuracy SP25 3D scanning probes with a broad range of styli, including a stylus calibration library. Optionally, get the Automatic Probe Changer (APC) with 6 or 9 stations and sensor-monitoring of APC positions to avoid probe pad collisions.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.