- Products

- Catalogs

- News & Trends

- Exhibitions

Metrology system 300GMSP nano

Add to favorites

Compare this product

Description

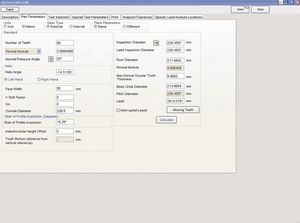

Inspect your parts right on the production floor - with results comparable to the lab. The Gleason 300GMSP nano Gear Metrology System for Production Environments saves time for part transport and standing in line in front of the inspection room. The P version offers all inspection and analysis capabilities of the 300GMS nano. In addition, its integrated compensation systems makes it resistant to typical production floor thermal and vibratory dynamics as well as contamination.

Helix angle

- 0 to 90°

Module - 0.4* to 18 mm

Workpiece length, max.** - 450 mm

Workpiece diameter, max. - 300 mm

Compensate External Dynamics

The 300GMSP nano features a host of integrated systems that compensate for typical production floor thermal and vibratory dynamics as well as contamination.

Lab-Level Inspection

The 300GMSP nano offers production floor inspection results comparable to the lab - without wasting time for part transport or parts lining up to enter the lab.

Evaluate Waviness on Submicron Level and Analyze Gear Noise

Measure submicron surface finish with a skidless probe, analyze waviness for profile, lead and pitch, including noise analysis with sophisticated software tools.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.