- Products

- Catalogs

- News & Trends

- Exhibitions

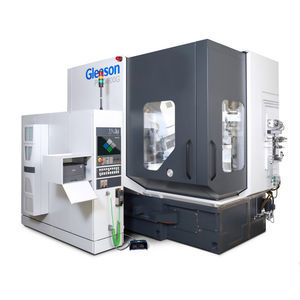

CNC gear-cutting machine Phoenix 280CXfor bevel gear

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Other characteristics

- for bevel gear

- Part diameter

Min.: 0 mm

(0 in)Max.: 280 mm

(11 in)- Gear hob diameter

Min.: 0 in

Max.: 9 in

Description

The Phoenix® Bevel Gear Cutting Machines are the most productive in their class with cutting cycle times significantly reduced. The 280CX is a highly automated solution for automotive and other gear manufacturers seeking efficient high volume production. The 280C offers jobbers the same performance benefits but in a simpler package without integrated automation.

Workpiece diameter, max.280 mm

Range of tooth numbers 1-300

Cutter diameter (FM), max.9"

Cutter radius (FH), max.105 mm

Maximum Stiffness, Minimal Vibrations

The 280C/CX Series features a special monolithic column design for maximum stiffness and minimal vibration during machining.

Reliable by Design

The Phoenix Series are built for maximum reliability including simplified guarding and excellent chip containment. The clean and simple design results in easier access and less overall maintenance.

First Part Checking

Operators like the integrated first part measuring cycle with its automated correction feature for easy and fast setup until the first part is cut to perfection.

Parallel AutoPath Chamfering

The CX version is equipped with a second tool spindle which allows parallel chamfering via the AutoPath Chamfering process while the next workpiece is being cut.

Integrated Automation

The integrated automation of the 280CX in combination with parallel chamfering guarantees a significant cycle time reduction.

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogsRelated Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Precision CNC milling machine

- High-precision CNC milling machine

- Gear-hobbing machine

- CNC gear-cutting machine

- CNC gear-shaping machine

- Gear-shaping machine

- High-power CNC milling machine

- Vertical gear-hobbing machine

- Horizontal gear-hobbing machine

- Gear shaving machine

- Vertical gear-shaping machine

- CNC gear shaving machine

- Horizontal gear shaving machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.