- Products

- Catalogs

- News & Trends

- Exhibitions

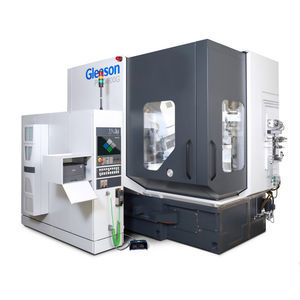

CNC gear-cutting machine Phoenix® 1000HCfor large-diameter partsfor bevel gear

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Other characteristics

- for large-diameter parts, for bevel gear

- Part diameter

Min.: 0 mm

(0 in)Max.: 1,000 mm

(39 in)- Gear hob diameter

Min.: 0 in

Max.: 18 in

Description

The Phoenix® 1000HC brings speed, accuracy and repeatability to large bevel gear cutting operations. The highly robust machine design and powerful CNC Controls provide maximum flexibility and reduce changeover times.

Workpiece diameter, max.1000 mm

Range of tooth numbers 1-300

Cutter diameter (FM), max.18"

Cutter radius (FH), max.350 mm

Reliable by Design

The Gleason 1000HC is built for maximum reliability including simplified guarding and excellent chip containment. The clean and simple design results in easier access and less overall maintenance.

Unsurpassed Productivity

The 1000HC provides optimum performance for PowerCutting® - for the toughest jobs in bevel gear manufacturing.

Versatile

Capable of both face hobbing and face milling; plus cutting of straight bevel gears, face gears, face clutches, power skiving and unimillTM.

Easy Changeover and Operation

The 1000HC's design brings cutter and workpiece closer to the operator allowing for easy access as well as easier loading - manually or automatically.

User-Friendly Control

The Gleason HMI greatly empowers even less experienced operators to create programs and operate the machine more productively. The 1000HC runs with the latest Fanuc 30i control.

Built-In Intelligence

Embedded condition monitoring alerts you of potential future issues. Problems are resolved before they happen.

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogsRelated Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Precision CNC milling machine

- High-precision CNC milling machine

- Gear-hobbing machine

- CNC gear-cutting machine

- CNC gear-shaping machine

- Gear-shaping machine

- High-power CNC milling machine

- Vertical gear-hobbing machine

- Horizontal gear-hobbing machine

- Gear shaving machine

- Vertical gear-shaping machine

- CNC gear shaving machine

- Horizontal gear shaving machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.