- Products

- Catalogs

- News & Trends

- Exhibitions

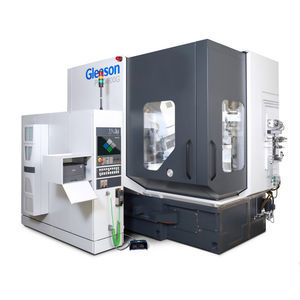

Quality test machine 600HTT CNCfor materialsfor bevel gear

Add to favorites

Compare this product

Characteristics

- Test type

- quality

- Operating mode

- CNC

- Test material

- for materials, for bevel gear

- Sector

- industrial

- Technology

- mechanical, gear

- Configuration

- compact

Description

The 600HTT Turbo Tester® has set the world standard for CNC-controlled roll testing of spiral bevel and hypoid gear sets. In addition to Basic contact pattern checking, this production- oriented machine provides single flank and structure-borne noise testing capabilities for soft and hard parts.

Workpiece diameter, max.600 mm

Pinion speed, max.3000 rpm

Flexibility

Fast, flexible gear tester for spiral bevel and hypoid gear sets.

Ergonomic Design

Compact ergonomic design, easy to operate and maintain.

User-Friendly Control

User-friendly Windows based software on a Fanuc 31i controller.

Up to 600 mm

For automotive and truck size application up to 600 mm gear diameter.

Innovative and Powerful

Contact pattern, Single Flank as well as Structure borne noise measurement up to 3000 rpm.

Catalogs

No catalogs are available for this product.

See all of Gleason‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.