- Metrology - Laboratory

- Metrology and Test Equipment

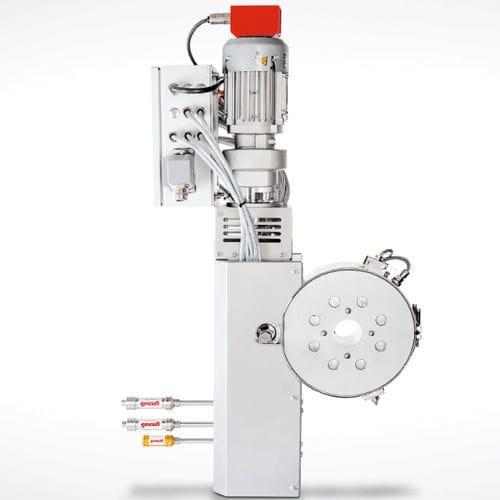

- Capillary viscometer

- Gneuß Kunststofftechnik GmbH

Capillary viscometer VISfor PETlaboratoryprocess

Add to favorites

Compare this product

Characteristics

- Type

- capillary

- Applications

- laboratory, process, for PET, for extrusion

- Configuration

- in-line

- Options and accessories

- rheometer

Description

The Online Viscometer was developed with the goal of achieving measurements which are comparable with laboratory results and to provide a system which provides these accurate values permanently and without influencing the process.

The viscometer is fitted between two flange connections. The melt channel can be designed according to the customer´s specifications between D = 20 mm (0.8 inches) and D = 110 mm (4.3 inches). The unit includes the pump drive, the pump, pressure transducers, temperature sensors and the control and evaluation electronics. Electric or liquid/vapor heating is available (optional). The setting of process parameters, the evaluation and the display is realized via a user-friendly touch screen panel or alternatively can be integrated into an existing control system.

An easily exchangeable capillary permits the adaptation of the measuring device to different viscosities ranging from 1 mPas (0.01 poise) up to 20.000 Pas (200,000 poise). A subsequent change of the measuring range is also possible.

Due to the special melt channel design and precise fabrication, dead spots or edges in which shear and temperature sensitive polymers could possibly stagnate can be avoided. The very short dwell time also prevents accumulations of degraded material. A further innovative feature is the possibility of completely cleaning all parts in contact with the melt without interrupting or disturbing the production process.

Configuration

By means of a high precision metering gear pump, a small part of the polymer melt (max. 3 kg / h or 7 lbs / h) is separated from the main melt channel. This is pumped through a precisely manufactured slot capillary.

Catalogs

No catalogs are available for this product.

See all of Gneuß Kunststofftechnik GmbH‘s catalogsOther Gneuß Kunststofftechnik GmbH products

POLYMER TECHNOLOGY

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.