- Food industry

- Other Food Machinery

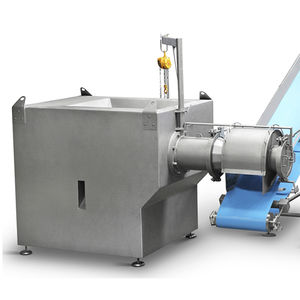

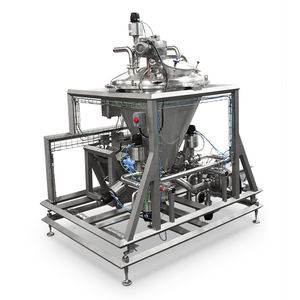

- Deaerator for the food industry

- Gold Peg International Pty Ltd

Vacuum deaerator for the food industry

Add to favorites

Compare this product

Characteristics

- Options

- vacuum, for the food industry

Description

The Vacuum De-aeration Vessel or Vacuum Flash Vessel is used to receive the cooked product from the RotaTherm® Direct Steam Injection Cooker and 'flash' cool the product to the required filling temperature and remove entrained air from the product.

You will find that being able to cook to one temperature and then subsequently cool the product to the required temperature, by the filling equipment, is a great benefit. This Gold Peg™ technology has the following features:

The body of this unit is made from food-approved material that provides resistance to build up - stainless steel and polypropylene are available

Temperature controlled

Product level management

CIP system and USDA compliant

Build-up prevention design

VIDEO

Catalogs

No catalogs are available for this product.

See all of Gold Peg International Pty Ltd‘s catalogsOther Gold Peg International Pty Ltd products

Food Processing Equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.