- Industrial machines and equipment

- Welding and Assembly

- Electrofusion welder

- Goldstone Orient New Material Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Electrofusion welder

Add to favorites

Compare this product

Characteristics

- Technique

- electrofusion

Description

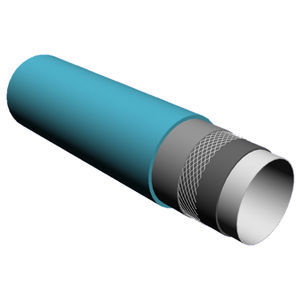

Electrical fusion is an electrical fusion process whereby outer sleeve fittings containing heating elements are installed in a polyethylene pipe and, when an electrical current is applied, the plastic in the pipe or fitting is melted and welded together. together to form a comprehensive Board.

Electric Fusion Fitting (linked to a PDF file) is a usually used for steel or fiber reinforced polyethylene pipe, where the butt fusion is not practicable, because the end of pipe has a reinforced middle layer. Prefabricated fittings are used, incorporating an electrical heating coil which melts the plastic of both the fitting and the pipe, causing them to fuse together.

After more than 20 years’ continuous developing on electric fusion fitting manufacturing, Goldstone now can supply various fittings from DN 50 up to DN 1200, which can meet flexible installation of pipeline.

Goldstone also provides customers with high performance electrofusion welding machine. The IEFD series is jointly developed by Goldstone technical team and welder factory, and the welding parameter is authorized by reinforced pipe manufacturers. The welder adopt RMS control, main suitable for connection of PE pipes and fittings, which are used for natural gas or water supply, it is the perfect corollary equipment for manufacturers or construction units of pipes and fittings.

Catalogs

No catalogs are available for this product.

See all of Goldstone Orient New Material Technology‘s catalogsOther Goldstone Orient New Material Technology products

Joint & Fittings

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.