- Hydraulics - Pneumatics

- Pump

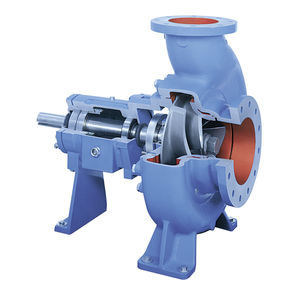

- Centrifugal pump

- Goulds Pumps

Centrifugal pump 3171 for chemicalsfor hydrocarbonswith electric motor

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- for chemicals, for hydrocarbons

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- stationary

- Domain

- industrial

- Applications

- discharge, process, for control, drainage, chemical process, sump, drainage

- Fluid specification

- for corrosive fluids

- Other characteristics

- heavy-duty, heavy-duty, vertical, jacketed

- Flow

722 m³/h

(25,497.18937 ft³/h)- Head

105 m

(344'05" )- Fluid temperature

232 °C

(449.6 °F)

Description

API 610 11th edition, compliant VS4 sump pump

The Model 3171 is the Veteran vertical sump and process pump. Thousands of installations in industrial process, sump drainage, corrosive liquids, pollution control, molten salts attest to the 3171's remarkable performance. Simple mounting.

Abrasive Liquids

Goulds sealed bearing arrangement is recommended for applications where abrasive solids are in the pumpage and no clean flush is available. A carbon bearing and lip seal is used for sealing the bearing housing. Spring loaded grease cup is provided.

Float Control

The widest range of float controls is offered to suit the individual requirements of every installation. Ask your Goulds representative for a complete list of options

Molten Sulfur Pumps

Jacketed column and discharge pipes (tested to 150 PSIG [1034 kPa]). Available in all principal alloys. One-piece, self-lubricating, graphite impregnated steady bearing Vapor-proof construction to seal sump vapors. Balanced, low NPSH, semi-open impeller for optimum performance. Multiple intermediate bearings permit overall settings to 20 feet (6 m).

Mounting Systems

Goulds can provide optional mounting systems to meet specific user requirements including pit covers fabricated with float control mounting points, man holes for access, vapor-proof designs, lube line holes.

Maximum Sealing Flexibility

Vapor-Proof Construction

Optional upper stuffing box allows use of wide range of sealing arrangements to meet specific user requirements for sealing toxic, hazardous, noxious or corrosive fumes. With this option, the discharge pipe and all fittings are sealed at the support plate.

Catalogs

Goulds 3171 / CV 3171

16 Pages

Goulds API 3171

8 Pages

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Submersible pump

- Suction pump

- Compact pump

- Lubricating oil pump

- Flow pump

- Mechanically-actuated pump

- Impeller pump

- Food product pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.