- Production Machines

- Forming Machine

- Mechanical press line

- GPM Machinery (Shanghai)

- Products

- Catalogs

- News & Trends

- Exhibitions

Mechanical press line GP seriesdoublecontinuoushot

Add to favorites

Compare this product

Characteristics

- Operation

- mechanical

- Structure

- double

- Other characteristics

- continuous, hot, cold, impact

Description

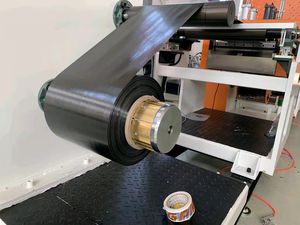

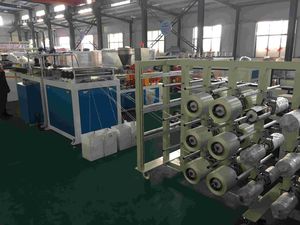

Double Belt Press Machine For Fiber Reinforced Thermoplastic Honeycomb Sandwich Materials Laminates

CFRT(Continuous Fiber Reinforced Thermoplastic composites) ——Is based on thermoplastic resin as matrix and continuous fiber as reinforcement material, a new type of thermoplastic composite material with high strength, high rigidity, high toughness, and recyclable that is formed through resin melt impregnation, extrusion and other processes.

CFRT BOARD

CFRT board is a kind of thermoplastic composite board which is made of CFRT unidirectional cloth and combined by one or more combinations of 0°, 45°, -45°, and 90°, laminated by hot and cold pressing. It can also be combined with other high-performance core materials, such as honeycomb panels, polyurethane foam, balsa wood, solid wood compressed sheet, or with non-woven materials to form a new sandwich composite sheet.

Advantages of the product: The continuous fiber can provide strength and rigidity to the greatest degree; the interlayer shearing performance of the product is excellent, and the impact strength is high; the layering type, thickness, reinforcing material type and fiber volume content of the plate can be customized to meet the customer’s requirements in different industries. ; product surface without fabric lines; corrosion-resistant, mold-proof, easy to clean, free from chemical cleaning agents; can be welded, easy to cut, install and repair; can be hot-pressed formed, with short molding cycle; partially replaces thermoset glass steel, Aluminum and stainless steel sheet, is suitable for light weight requirements of transportation; green, recyclable and sustainable.

Other GPM Machinery (Shanghai) products

Thermoplastic Composites Machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.