- Production Machines

- Other Manufacturing Equipment

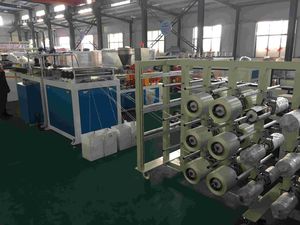

- Profile production line

- GPM Machinery (Shanghai)

- Products

- Catalogs

- News & Trends

- Exhibitions

Profile production line prepregcontinuous

Add to favorites

Compare this product

Characteristics

- Finished product

- profile, prepreg

- Other characteristics

- continuous

Description

Using melt imprégnation process produce nylon(PA)+continuous carbon fiber reinforced Thermoplastic unidirectional tape prepreg(CF UD tape);

1,using fiber types: carbon fiber or glass fiber;

2,Use extruder model: single screw extruder or twin screw

extruder;

3,PA: Carbon fiber = 50% : 50%;

4,Can using plastic raw materials: PA/PP/PE;

5,Production product thickness: 0.2-0.25 mm;

6,Produce - product width: 360mm/635 mm;

The continuous carbon fiber reinforced PA UD tape prepreg has no stickiness on the surface, so it is necessary to use a double-belt presses for laminating processing. First, the PA UD tape is manually laid, and then laminated according to the required thickness to form a PA UD tape laminate. The lamination processing temperature is between 230°C and 270°C.

The advantages and disadvantages of continuous carbon fiber reinforced PA prepreg will directly affect the performance of UD tape laminate. The continuous carbon fiber reinforced PA prepreg has a high tensile strength to ensure the strength performance of the UD tape laminate.

Other GPM Machinery (Shanghai) products

Thermoplastic Composites Machine

Related Searches

- Production machine

- Automatic making machine

- Pipe making machine

- Continuous production machine

- Food production line

- Coiler

- Profile making machine

- Construction making machine

- Automatic coiler

- Textile making machine

- Tube coiler

- Non-woven production machine

- Production line for the automotive industry

- Melt-blown production line

- Rotary production line

- Plastic film coiler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.