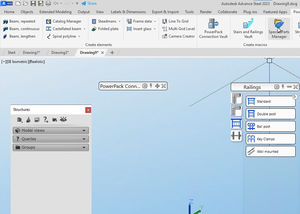

CAD software Advance workshopmanagementcontroltracking

Add to favorites

Compare this product

Characteristics

- Function

- CAD, management, control, tracking, CAM, ERP, tracing, scheduling, MES, manufacturing execution system, BIM

- Applications

- process, machine

Description

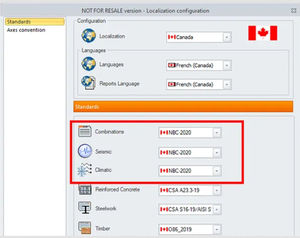

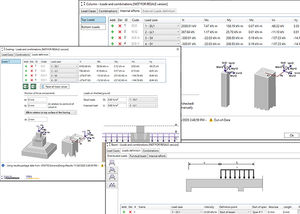

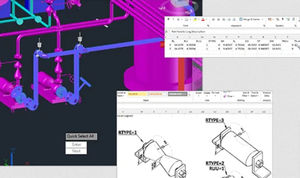

Advance Workshop is a manufacturing execution system(MES) developed for the rebar,steel and precast fabrication industries. It optimises factory machine productivity, transport and stock levels and conforms to all major code standards globally. The system can import cad drawings, IFCs and BIM model information to enable efficient execution of all fabrication processes needed to transform from raw material to finished product ready for delivery.

Why use Advance Workshop

Saves production time and increases efficiency through optimising fabrication processes with all known machinery formats

BIM workflows

Imports BIM data through IFC compatibility and is able to extract necessary production data like rebar lists.

Traceability

Gives complete tracking of raw material data through goods received through production and then delivery to site

Subcontracting

Automate the PO, Billing and invoicing process with your preferred subcontractors.

ERP interface

Connect Advance Workshop to existing ERP systems in order to generate automatic and accurate payroll data for employees.

Real Time data

Access to real time production data to give accurate decision making information.

Transport- GPS

Inbuilt GPS enabled logistical system allows precise scheduling of daily delivery requirements with entire truck /haulier fleet.

The 5 key benefits of Advance Workshop

Save 30% time on your production programme

Improve your decision making with real time access to factory data

Our onsite Implementation experts will ensure smooth onboarding and activating of our system

Full time technical support available throughout normal working hours

VIDEO

Catalogs

No catalogs are available for this product.

See all of GRAITEC‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- Online software

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Automated software

- Machine software

- Engineering software

- EDM software

- Creation software

- Reporting software solution

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.