- Products

- Catalogs

- News & Trends

- Exhibitions

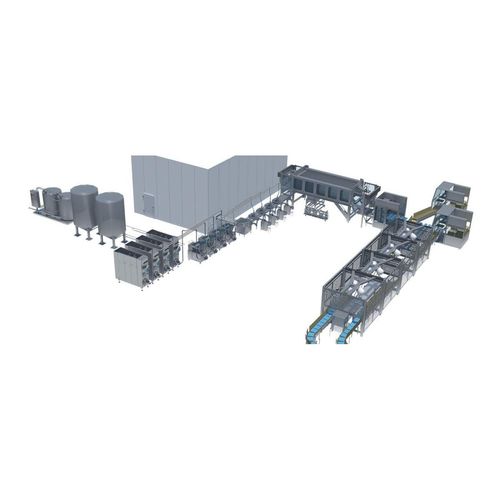

Food extrusion line BT

Add to favorites

Compare this product

Characteristics

- Type

- food

Description

BT extrusion lines are production lines for high-speed extrusion of sticks, sandwiches, ball top cones, bars, logs and cakes, and hardening of cones, cups, bulks etc.

64 BT lines have been delivered to leading producers of ice cream around the world during the last 10 years. This is a clear statement that our quality and know-how are highly valued by our customers.

The Gram Equipment BT extrusion lines are the latest generation of extrusion and hardening lines designed from the ground up for the ice cream industry. The design of the tunnel is based on a well-proven concept that through optimized airflow, increases the hardening efficiency. This state-of-the-art model provides full product versatility, set-up flexibility, advanced electronic synchronization, integrated performance monitoring, and exceptional hygienic standards.

Tunnel system

Benefits & features

• Sequential defrost with three evaporators (2 in operation, 1 in defrost). Saves energy and maintains constant temperature in tunnel with increased and constant ice cream product quality.

• Air balance system minimizes humid air from production to inside the tunnel

• ProFlow control of airflow in tunnel

The Worktable

Benefits & features

• Format change optimized; settings are maintained for each extruder head

• Tray cleaning without defrosting “instant wash”

• Flexible worktable layout

• Product in position guidance, “laser view”

• Tensioning system is placed on worktable, outside tunnel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.