- Production Machines

- Other Manufacturing Equipment

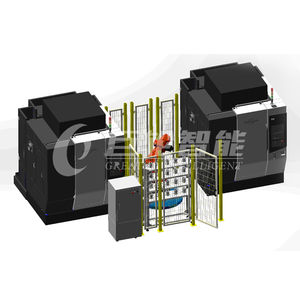

- Automatic production line

- GREATOO INTELLIGENT EQUIPMENT INC.

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic production line continuousflexiblerobotic

Add to favorites

Compare this product

Characteristics

- Other characteristics

- automatic, continuous, flexible, robotic

Description

Flexible production line automation electrode by four Fagor system three-axis electrode processing center, one 20 kg six degrees of freedom, industrial robot, 1 of article 15 meters of linear guide, 80 location library the workpiece and the security fence, security door and related peripheral equipment. Production line is controlled by a set of flexible production management system, implementation: the staff use PC after distribution processing tasks, the production department management system according to robots and CNC automatic scheduling task information, to realize automatic robot for CNC automatic up-down and CNC machining, under the condition of a single intervention to complete the function of automatic production.

Equipment use: used to implement the graphite electrode processing automation

Class 3 continuous production equipment using divisions: 7 days/week

Equipment using the environment:

Temperature: Max. 50 ° C relative humidity: Max. 95%

Energy:

Power supply: three-phase ac 380 v, 220 v communication

Compressed air: 0.6 Mpa to 0.7 Mpa

Production line control system, is the core of realizing automation production. With adding production tasks, the production data management, material warehouse management, equipment management, production scheduling, production safety management, and other functions. For automatic production line control system, as the brain controls the whole production line operation.

Processing center, processing center can use FAGOR, FANUC system of machining center, etc. According to the practical production requirements.

Other GREATOO INTELLIGENT EQUIPMENT INC. products

Intelligent Production Line

Related Searches

- Production machine

- Automatic making machine

- Continuous production machine

- Flexible production machine

- Assembly line production line

- Earloop face mask production machine

- Making machine with touch screen

- Production line for the automotive industry

- Folding production line

- Robotic production line

- Strap production line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.