- Machine-tools

- Machining Center

- 3-axis machining center

- GREATOO INTELLIGENT EQUIPMENT INC.

- Products

- Catalogs

- News & Trends

- Exhibitions

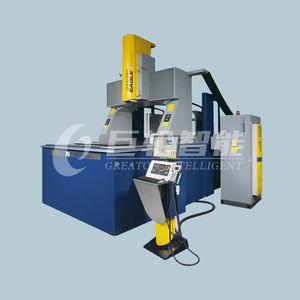

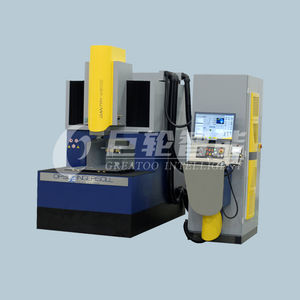

3-axis CNC machining center HSM600verticalgantryfor marble

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Structure

- gantry

- Machined material

- for marble

- Number of tool stations

- 24 tools

- Associated functions

- milling, tapping, drilling

- Applications

- for molds

- Other characteristics

- high-speed, high-performance, high-speed, high-precision, high-rigidity

- X travel

650 mm

(25.59 in)- Y travel

520 mm

(20.47 in)- Z travel

320 mm

(12.6 in)- Rotational speed

30,000 rpm

(188,496 rad.min-1)- Power

8.5 kW

(11.56 hp)- Work feed X-axis

40,000 mm/min

(26 in/s)- Work feed Y-axis

40,000 mm/min

(26 in/s)- Tool weight (max)

3 kg

(6.6 lb)- Positioning accuracy

0.005 mm

(0.0002 in)- Tool-changing time

1.2 s

- Weight

5,000 kg

(11,023.11 lb)- Overall length

1,960 mm

(77.2 in)- Overall width

2,450 mm

(96.5 in)- Overall height

2,680 mm

(105.5 in)

Description

high-speed machining center with high rigid gantry frame structure design, lathe bed, column base of machine tool machine tool such as the use of advanced marble material, has excellent damping vibration reduction performance, low thermal expansion coefficient, high corrosion resistance and good mechanical properties, high heat stability, high damping vibration reduction performance and high dynamic and static mechanics performance, meet the requirements of the high speed precision and efficient processing. Widely used in mould and parts, milling, drilling, tapping and other manufacturing production has quick speed, high precision, processed products high quality, stable performance, low cost advantages.

HSM600 high-speed machining center with high rigid gantry frame structure design, lathe bed, column base of machine tool machine tool such as the use of advanced marble material, has excellent damping vibration reduction performance, low thermal expansion coefficient, high corrosion resistance and good mechanical properties, high heat stability, high damping vibration reduction performance and high dynamic and static mechanics performance, meet the requirements of the high speed precision and efficient processing. Widely used in mould and parts, milling, drilling, tapping and other manufacturing production has quick speed, high precision, processed products high quality, stable performance, low cost advantages.

Other GREATOO INTELLIGENT EQUIPMENT INC. products

Nc Machine Tool

Related Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- 24 tools CNC machining center

- 40 tools CNC machining center

- 4-axis CNC machining center

- High-speed CNC machining center

- Mold CNC machining center

- 32 tools CNC machining center

- Tapping CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.