Compressed air filter BFh seriesbagindustrialstainless steel

Add to favorites

Compare this product

Characteristics

- Designed for

- compressed air

- Filtration element

- bag

- Applications

- industrial

- Material

- stainless steel, polyester, polypropylene

- Cleaning

- continuous

- Other characteristics

- horizontal

- Operating pressure

5.7 bar

(82.672 psi)- Flow

Max.: 180 m³/h

(6,356.64 ft³/h)Min.: 20 m³/h

(706.293 ft³/h)- Fluid temperature

190 °C

(374 °F)

Description

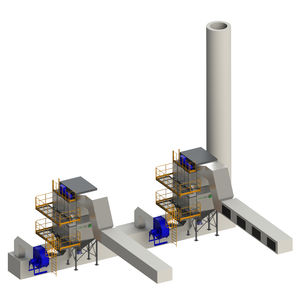

With horizontal arrangement of filter elements and continuous pulse regeneration.

1. Compressed air receiver

Accumulates compressed air and supplies it to the sliding gear for regeneration.

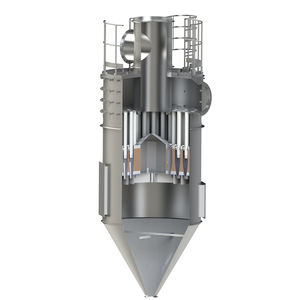

2. The modular unit of the filtering bags

The unit consists of 10 filter elements, which allows varying the overall dimensions - to optimally

place the filter of the required performance in the room or on the site.

3. Sliding gear

Performs continuous regeneration of the bag filter without disconnecting part or all of the filter.

4. Storage bunker with dust unloading system

Accumulates collected dust for further unloading.

5. Programmed logic controller plc

The automation system is carried out based on an industrial controller. All electric motors are equipped with frequency converters. PLC provides automatic operation of the bag filter and controls the parameters:

Inlet pressure at the bag filter

Outlet pressure

Pressure drop

Inlet temperature at the bag filter

The level of dust accumulation in the bunker.

Catalogs

greenex catalog 2021

17 Pages

Related Searches

- Filter for industrial applications

- Centrifugal classifier

- Stainless steel separator filter

- Process classifier

- Gas pre-filter

- Compressed air separator filter

- Bag filter

- Activated carbon pre-filter

- PP filter

- Cyclone classifier

- Continuous pre-filter

- Polyester pre-filter

- Vertical classifier

- Gas separator

- Horizontal filter

- Cast iron separator

- Odor adsorption filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.