- Packing - Handling - Logistics

- Packing and Packaging

- Automatic filling machine

- GREIF-VELOX Maschinenfabrik GmbH

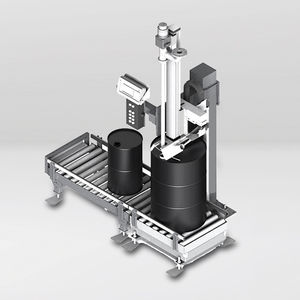

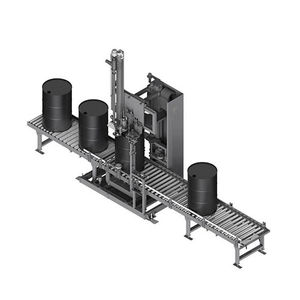

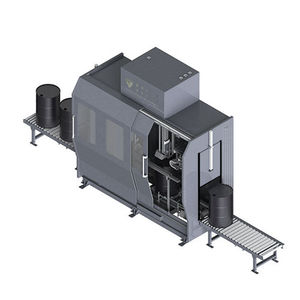

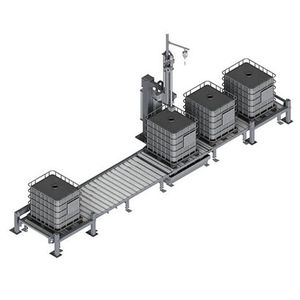

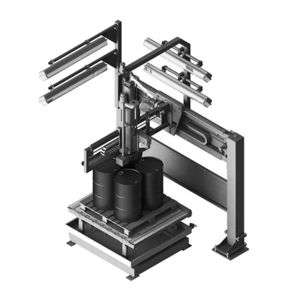

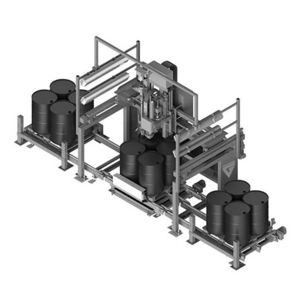

Pallet drum filling system R-DOSfully-automaticsemi-automaticIBC

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic, semi-automatic

- Container type

- IBC, pallet drum

- Product applications

- food, for low-viscosity liquids

- Domain

- for the food industry, for the chemical industry

- Type

- vertical

- Other characteristics

- explosion-proof

- Throughput

12 p/h, 55 p/h

Description

Your challenge is to fill your products into very diverse containers such as drums, IBCs or canisters? - Then you've come to the right place with our pallet filling systems. The special highlight - you save expensive palletising technology for full containers by placing the empty containers on pallets and filling them upright on the pallet.

INDIVIDUALISATION

Whether you fulfil your task with our semi-automatic all-rounder or our fully automatic camera-based portal filling system - your specific application, consisting of your product, your containers and your performance requirements, will lead you precisely to the right equipment. Our experience from hundreds of completed projects with a wide variety of additional equipment enables us to find the best solution for your task. The integration of pallet transport technology, palletising and labelling technology or load securing enables the delivery of a full-line solution from a single source - from our company.

APPLICATION AREA

• Filling of palletised containers using the under-bung, under-mirror or over-mirror method

• Products with low to high viscosity (1 to 50,000 mPas at 20°C)

• Industries: Chemicals, petrochemicals, food, building materials

OUR ADVANTAGES

• excellent price-performance ratio

• simple operation via touch panel with visualisation

• control of your product pump or a pilot valve included

• ERP connection (bidirectional)

• future automation or system expansion by PLC possible as standard

• Expanded range of containers through the use of up to 3 scales

ACCESSORIES/EXTENSIONS

• explosion-proof version

• stainless steel version

Catalogs

No catalogs are available for this product.

See all of GREIF-VELOX Maschinenfabrik GmbH‘s catalogsOther GREIF-VELOX Maschinenfabrik GmbH products

Individual components - LIQUIDS

Related Searches

- Automatic filler

- Wrapping machine

- Liquid filler

- Filler for the food industry

- Automatic wrapping machine

- Stretch film wrapping machine

- Strapping machine

- Food product filling machine

- Automatic strapping machine

- Semi-automatic filler

- Filling system for the chemical industry

- Complete packaging line

- Case packer

- Semi-automatic wrapping machine

- Bag filler

- Wrapping machine with conveyor

- Powder filler

- Rotary arm wrapping machine

- Granulate filler

- Filler with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.