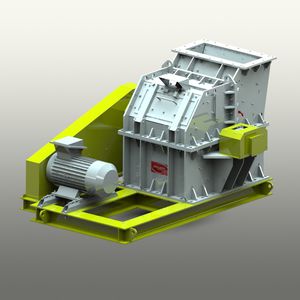

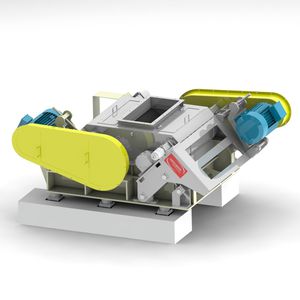

Hammer crusher stationary

Add to favorites

Compare this product

Characteristics

- Technology

- hammer

- Mobility

- stationary

Description

The crushing and the grinding determine two basic steps which condition the optimization of the calcinations unit. Our equipment adjusts the gypsum particle size and controls the feeding flow at GRELBEX® kiln's inlet.

GRELBEX® jaw crusher allows the products fragmentation by crushing between two jaws: one fixed and one mobile driven by an eccentric shaft coupled to an electric motor.

GRELBEX® hammer crusher allows the materials reduction by percussion effect with the mean of articulated hammers and rotating to high speed in an armored grinding chamber. The discharge products calibration is ensured by removable bars grid with adjustable space.

Catalogs

No catalogs are available for this product.

See all of GRELBEX‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.