- Metrology - Laboratory

- Laboratory Equipment

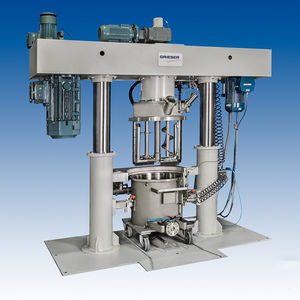

- Paddle mixer

- Grieser Maschinenbau- und Service GmbH

Paddle mixer BF seriesbatchsolid/liquidpowder

Add to favorites

Compare this product

Characteristics

- Technology

- paddle

- Batch/continuous

- batch

- Product type

- solid/liquid, powder

- Configuration

- vertical

- Other characteristics

- vacuum, compact, automatic, combined heating/cooling, ATEX

- Applications

- laboratory, chemical process vessel, for medium-viscosity liquids

- Engine power

Max.: 7.5 kW

(10.2 hp)Min.: 3 kW

(4.08 hp)

Description

The butterfly mixer is used for deagglomeration and wetting of solids in a liquid base for products in the medium viscous range, for example, for plasters, adhesives, sealants and insulating materials.

Properties

The design is very similar to the laboratory dissolver, but it is much more robust with regard to the higher mixing forces during operation. The laboratory and pilot plant-butterfly mixers are particularly suited for analyzing and optimizing the mixing process. The derived process knowledge can be used to scale up the machine to the desired production size.

Laboratory Butterfly Mixer, Type BFM 30 L, with 3,0 kW drive power and a mixing shaft speed between 300 – 4.000 1/min.

Pilot Plant Butterfly Mixer, Type BFB 30 T, with 3,0 up to 7,5 kW drive power and a mixing shaft speed between 200 – 2.300 1/min.

Design with form-fitting vessel clamps.

Options and versions

• Vacuum design with vacuum unit and vacuum control

• One or two-armed wall scraper

• Integrated tempering system (Heating and/or cooling)

• Double jacket and/or double bottom

• Filler / powder feed below product level enabled by vacuum suction

• FDA, GMP or SIL compliant design

• Explosion protection according to ATEX

• Digital pressure, temperature, speed and/or electrical power measurement

• Automatic speed reduction control

• Oxygen or gas measurement monitoring systems

• Hard-wired relais control (VPS), compact controller or programmable logic controller (SPS)

• Automatic mixing sequences with variable time, speed and vacuum setting

• Recipe management and dosing control

• Batch related logging of operational, process and production data

• Touch screen panel with process visualization

Catalogs

Other Grieser Maschinenbau- und Service GmbH products

Products

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Solid blender

- Vertical agitator

- Agitator for the chemical industry

- Powder blender

- Solid/liquid homogenizer

- Paddle blender

- Compact agitator

- Vacuum homogenizer

- High-speed homogenizer

- Automatic homogenizer

- Laboratory homogenizer

- Explosion-proof agitator

- ATEX agitator

- Conical screw blender

- Chemical plant engineering agitator

- Mixer with heat exchanger

- Multi-axis mixer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.