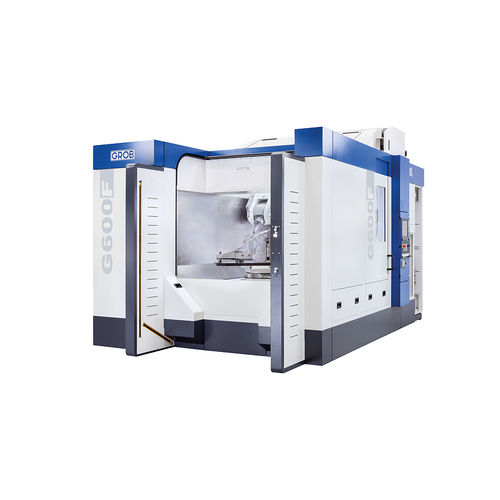

3-axis CNC machining center G600Funiversalfor aluminumHSK A-63

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- universal

- Machined material

- for aluminum

- Spindle mount

- HSK A-63

- Applications

- for the automobile industry

- X travel

1,500 mm

(59.06 in)- Y travel

1,265 mm

(49.8 in)- Z travel

1,100 mm

(43.31 in)- Rotational speed

18,000 rpm

(113,097 rad.min-1)- Power

20 kW, 29 kW, 40 kW

(27.19 hp, 39.43 hp, 54.38 hp)- Work feed X-axis

95 m/min

- Work feed Y-axis

60 m/min

- Work feed Z-axis

50 m/min

- Table load capacity

635 kg, 750 kg

(1,400 lb, 1,653 lb)- Positioning accuracy

0.01 mm

(0.00039 in)- Weight

20,000 kg, 22,000 kg

(44,092.45 lb, 48,501.7 lb)

Description

With optimized chip transport and high machine dynamics, the G600F machine variant achieves outstanding results for machining frame structure and chassis parts and battery housings.

The 1,550 mm interference range diameter, long travel paths and a swivel head with a range of 180 degrees make the G600F the ideal solution for complete 5-sided machining in your automated manufacturing facility.

The benefits at a glance

Best chip fall

High dynamics

High manufacturing flexibility

High machining accuracy

Customer-specific part loading

As a stand-alone machine or linked in the system

Suitable for MQL machining operations

Compact external dimensions

Machine concept

Kinematics

Version with established AC-kinematics and long travel paths in the X-,Y'- and Z-axes

Chip transport

Automatic chip removal to the rear of the machine

Individual automation

Available with manual or automatic front loading or automatic top loading, and optionally with integrated pallet changer.

Interference diameter

Up to 1,750 mm (with restricted Y-travel path) or up to 1,550 mm (no restriction)

Spindle versions

Besides the broad range of spindles, the motorized spindle designed and manufactured by GROB is the preferred choice for optimized process design. This spindle is perfectly matched to the G600F and has optimized quality features.

GROB Spindle Diagnostics (GSD)

GROB spindle diagnostics is a system that automatically monitors the condition of the motorized spindle. Benefits are a prolonged motorized spindle useful life, reduced tool wear and scheduled maintenance.

VIDEO

Catalogs

Other GROB-WERKE products

Machining centers for frame structure and chassis parts

Related Searches

- GROB machining center

- GROB vertical machining center

- GROB 3-axis machining center

- Precision CNC machining center

- GROB 5-axis machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- Gantry CNC machining center

- High-rigidity CNC machining center

- GROB milling machining center

- GROB high-productivity machining center

- Cutting CNC machining center

- GROB aluminum machining center

- GROB machining center with pallet changer

- GROB horizontal machining center

- GROB compact machining center

- GROB machining center for the automobile industry

- Turning-milling machine

- CNC turning-milling center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.