- Packing - Handling - Logistics

- Conveying

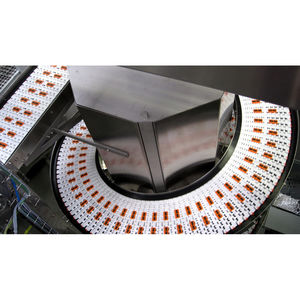

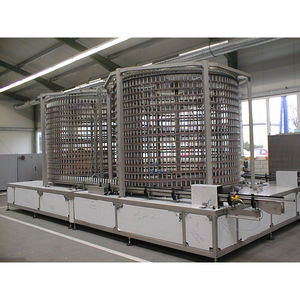

- Conveyor accumulating table

- Gronemeyer Maschinenfabrik GmbH & Co.

Conveyor accumulating table

Add to favorites

Compare this product

Characteristics

- Options

- for conveyor

Description

The Gronemeyer accumulation table can store large quantities of glasses, bottles or tins. The products are pushed to the accumulation table if there is backlog. The products are later re-fed into production by operating the system in reverse. The machine works according to the First In-Last Out principle.

In case of malfunction, the electrical control system activates the accumulation table based on sensor messages. After the malfunction ends, the stored products are automatically fed into the line.

Technical data:

-Chain width: up to 3,000 mm

-Usable chain length: up to 20 m

-Independent electrical control system

Optional equipment:

-Complete machine cover made of Makrolon with maintenance doors

-Loading and unloading belts

-Insulated module with air conditioning technology for perishable goods

Catalogs

No catalogs are available for this product.

See all of Gronemeyer Maschinenfabrik GmbH & Co.‘s catalogsOther Gronemeyer Maschinenfabrik GmbH & Co. products

conveying technology

Related Searches

- Rail conveyor

- Belt conveyor

- Conveying belt

- Conveyor for the food industry

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Transfer chain

- Modular conveyor

- Bulk products conveyor

- Discharge conveyor

- Curved rail conveyor

- Carton conveyor

- Automatic conveyor

- Metal conveyor chain

- Vertical conveyor

- Aluminum conveyor

- Rail-mounted conveyor

- Process conveyor

- Cylinder conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.