- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Gronemeyer Maschinenfabrik GmbH & Co.

Belt conveyor feedfor bottlesfor cans

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Function

- feed

- Transported product

- for bottles, for cans

Description

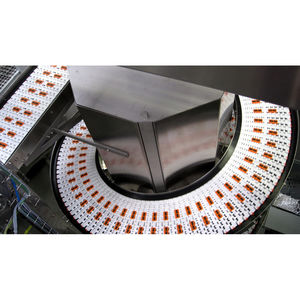

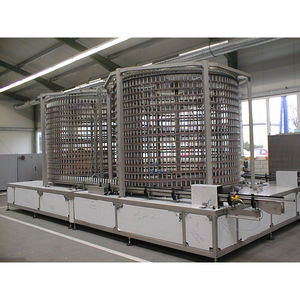

The Gronemeyer aligner station is a solution if you have to feed glasses, bottles or tins aligned into a filling or labelling machine. By using high-performance product identification up to 350 products/min. can be identified and aligned in a continuous flow of materials. New products can easily be saved with the electrical control system's user-friendly operator interface.

Technical data:

-Conveyor performance: up to 350 items/min.

-Installation length: 1500 mm (identification and alignment)

-Infinitely variable adjustment to product height and width

Optional equipment:

-Camera housing against the influence of other light

-High-speed camera for precise alignment even at high conveyor performance

-Automatic discharging of faulty products

Catalogs

No catalogs are available for this product.

See all of Gronemeyer Maschinenfabrik GmbH & Co.‘s catalogsOther Gronemeyer Maschinenfabrik GmbH & Co. products

conveying technology

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Conveying belt

- Conveyor for the food industry

- Drag chain conveyor

- Stainless steel conveyor

- Food conveyor

- Transfer chain

- Modular conveyor

- Bulk products conveyor

- Discharge conveyor

- Feeding conveyor

- Curved rail conveyor

- Carton conveyor

- Automatic conveyor

- Metal conveyor chain

- Vertical rail conveyor

- Conveyor for process applications

- Aluminum conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.