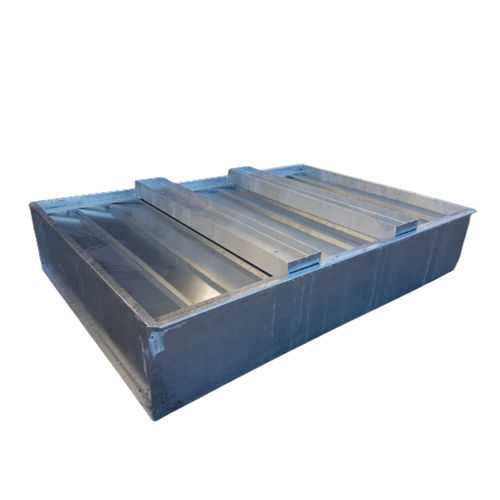

The ERT-F-W range of bunds is part of SANERGRID®‘s ERT® family of transformer fire protection bunds and comprises a series of standardised bund references with integral dielectric containment and fixed beams (F) in the width direction (W), particularly where the centre-to-centre distance of the transformer is known.

Description of the ERT-F-W standard range :

S235 steel tank, thickness 3, 4 or 5 mm; hot-dip galvanising certificate to ISO EN1461-2022.

Double sealed welds on all parts of the retention zones to guarantee a completely watertight tank, with individual quality inspection before leaving the factory.

The upper part of each tank is fitted with an EXTICOV CCF fire extinguishing system consisting of single-slope fire dampers tested by CNPP.

A set of 2 support beams is fitted widthways (W) above each ERT-F-W tray, making it easy to place the equipment on the trays.

These are fixed (F) and are welded to the trays at centres that comply with the ECODESIGN. All dimensions are available on the technical data sheet. On request before ordering, we can adapt to a special centre-to-centre distance if required.

The maximum allowable load (or MAL) for each tray is calculated and supplied for each tray with an additional safety coefficient to accommodate the transformer on its support beams.

At the foot of the bund, two watertight wall penetrations are available to accommodate 1.5-inch ¼-turn valves: the first valve to allow the bund to be drained, and the second to fit an SPI® PETRO PIT rainwater filtration kit. In the standard version, the bund is supplied with the two wall passages sealed with stainless steel plugs.